WEEK 134

Michael

Origin : Malaysia

Watchmaking class: Technician & Fullskill

Current mood: I have been practising some countersinks and experimenting with the Geneva stripes. It was very hard to make a proper Côtes de Genéve. It should be a thin layer and not deep cuts that will destroy the bevelling. I shall continue next week! Have a great weekend everyone!

Kind Regards,

Michael Lau

Renato & David

Origin: Zug, Zürich, Switzerland

Watchmaking class: Fullskill

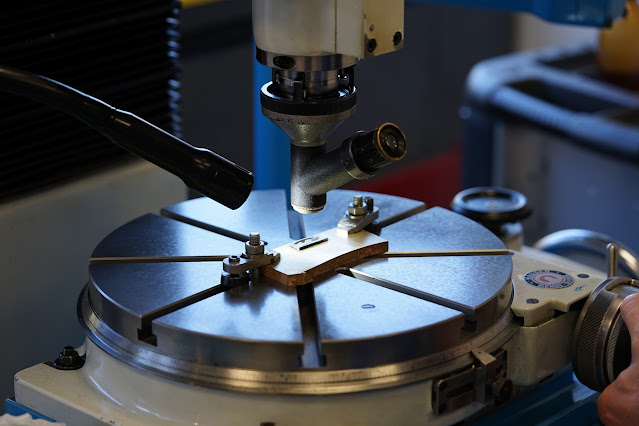

Current mood: Worked on a new setting lever for one of my pocket watches. I already made the pantograph drawing earlier. We figured it would be a nice exercise to do the whole lever on the jig borer. After drilling the two holes, the rest was mainly milling by rotation and radius adjustments around the rotation centers. Lots of measurement and angle calculation had to be done. Also interesting how the jig borer behaves when milling due to the lower rigidity vs. a milling machine. I now have very good control over the jig borer, especially with regards to milling. Excellent exercise! Renato

This week I moved on to finishing the tools that we have working on before the winding stems. I created 2 screw heads and m4 threads for them. I sandblasted one of them to see what kind of finishing I would get. The second I left with a machined finish. We also tested plating parts. David

Francesco, Åsmund & Robert

Origin: Italy, Norway, USA

Watchmaking class: Fullskill

Current mood: Hello everyone, this week I used the Schaublin 102 for the first time, I got really surprised how stable and how handy it is. I needed it for a special attachment for the polishing tripod.

In the second part of the week I started finishing a pallet fork bridge from an old Tissot.

I’m practicing with internal and external bevels, it takes so much time!

See you soon,

Francesco.

Hello,

This week I mostly just practiced on black polish, blueing and making brass matt. Spent very long time experimenting with making large brass surfaces matt and getting it perfect without any micro scratches. Getting close, but not as perfect as I want. Also going to black polish all the screws in my 6498, but they are round so all of them has so be flattened. So I’m going to spend the weekend doing that

Have a nice weekend.

Å

This week was an introduction to:

-The standing grinder and it's functions and perils (loose clothing, ties, strings on hoodies...),

-Plating and the various metals available,

-Heat treatment and blueing of steel parts.

Otherwise, it was a continuation of last week, with work on bevelling and different methods to do it on inside and outside corners/angles.

While making tools, and selecting screws to use with them, it gave me a deeper appreciation for all the miniature sizes of screws. A tip-o'-the-hat to all the companies and people that make these fasteners in diminutive sizes, for reference, look at the size of a comma for a "small" example.

Weather here in Le Locle: The sun is shining every day, but the sounds of ice being scraped off windshields is heard every morning.

Have a good weekend!

Robert

STEP 1: PART MAKING! (RENATO)

STEP 2: TOOL MAKING! (FRANCESCO)

STEP 3: FROSTING! (DAVID)

STEP 4: MAKING SCREWS! (DAVID)

STEP 5: GENEVA STRIPES! (MICHAEL)

STEP 6: BOOKS! (KHWCC LIBRARY)

HENRIK's WORDS:

Got really great fall weather in Le Locle! This week we continued practicing the various finishing techniques from last week and also learning the heat treatment of steel as well as electroplating the parts with black rhodium and red gold, We also continued with the tool making as well and Renato milled a setting lever in the jig borer, Francesco made his very fancy balance supporting tool, very good machining exercise! Next he has to finish all the surfaces! it was an interesting week as it was really diverse! Have a great weekend everyone!

No comments:

Post a Comment