WEEK 133

Michael

Origin : Malaysia

Watchmaking class: Technician & Fullskill

Current mood: It was a very busy week! Did some bevelling and finishing on steel. It was hard. First time doing it and it was a good start, more room for improvements. I also did some tools for black polishing and Geneva stripes. Looking forward to next week! Have a good weekend everyone!

Renato & David

Origin: Zug, Zürich, Switzerland

Watchmaking class: Fullskill

Current mood: Continued practicing various finishing techniques this week. Countersink polishing, matt finish on steel and brass, black polishing, corner filing. Also did Geneva stripes. Setup is everything there and then it's relatively easy to do. It was great to have another week to experiment and get more routine after the finishing week. It's all about the details and I figured out plenty of them this week :) Renato

This week I worked on skeletonizing a 6497 movement. I learned a lot of finishing, using the hand motor. I also learned what areas to avoid when skeletonizing in order to keep the integrity of a bridge or a mainplate. I also tried frosting finishing. David

Francesco, Åsmund & Robert

Origin: Italy, Norway, USA

Watchmaking class: Fullskill

Current mood: This was a full week of making some tooling, and spending time on putting bevels on small parts. And...most parts in watches happen to meet that category of "Small parts".

The beveling, for a beginner, can be very exasperating, just a small movement of the file, at a wrong angle, and you have to make corrections in that section of beveling, and perhaps in the adjacent beveling.

This is one of the skills where speed is not on your side, mistakes are easy to come by, and hard to fix.

The tool making was a way to step away from beveling for a breather and make tools we will use, adding a little bit of pattern for grip.

Robert

Hi everyone, this week I kept on with finishing.Yesterday I’ve just completed the yoke from the ETA 6498. I decided to change its shape, I filed until I got a a sharp external corner. Then I finished the flanks, the bevels and at the end I decided to do the matt surface on the flat surface. I started with the 800 paste but the grains where too small so I passed to the 600, it’s a bit coarser but in my opinion it turned out better.

Now I’m practicing with a bridge doing counter-sinks.

I’ve also ended with the aquamarine stones, I ground them until I got a round shape and I put it in the screw head of the scissor tool for the balance wheels.

See you next week,

Francesco

STEP 1: FINISHING TECHNIQUES COURSE! (KALLE, EDWIN, EWOUD)

STEP 2: FINISHING WEEKII! (FULLSKILL)

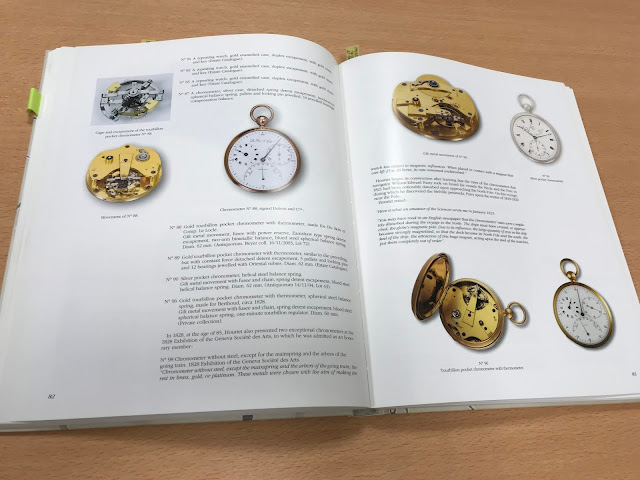

STEP 3: BOOKS! (KHWCC LIBRARY)

HENRIK's WORDS:

It got even busier this week! We had Kalle,

Ewoud, and Edwin from Chronoglide in Holland taking the Finishing Techniques

class this week, as its only one week we only have time to try out techniques

and see how they work in principle, but we covered a lot; bevelling, graining

flanks with two different techniques, black polishing, making and polishing

countersinks, Geneva stripes, spotting, two different techniques of straight

graining, and even some more techniques. The Fullskill class continued in the

other workshop to practice what they learned last week as well as continuing

with their tool manufacturing, indeed very enjoyable and fun week! have a great weekend everyone!

No comments:

Post a Comment