WEEK 102

Willy, Yuriy, Alex, Michael

Origin : Singapore, Canada, Taiwan, Malaysia

Age: n. a.

Watchmaking class: Technician & Fullskill

Current mood: Oscillator time!

This week we continue the balance build/repair topic. Replacing balance staff is a significant aspect of proper time keeping.

Old balance staff must be properly removed first. Henrik explained several different methods of this operation. Each has its own pros and cons. It was interesting to see how each method works on various balance wheels of different makes and materials. My favorite method is by using lathe to remove exact amount of material to make sure the old staff is removed securely without damaging the wheel or altering its geometry. It was eye opening experience observing how brass could be strong on time of intense and momentary impact. As well as steel loses its strength rapidly when its thickness is decreasing.

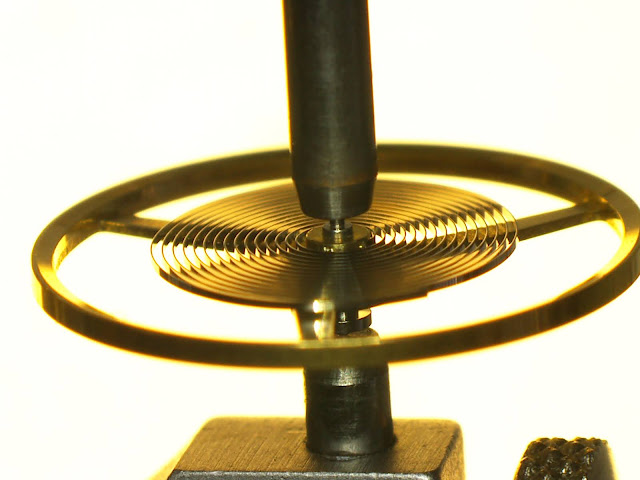

After removing old/broke staff, a new staff should be installed. Two days the workshop was full of tapping sounds of small hammers, riveting new staffs on exact place. Like dozens of woodpeckers doing their job. We also finished all the static poising and truing the balance wheels in the flat as well. We then started to work on the hairsprings by first learning how to pin them up on the collet and practicing truing them in the round and flat.

Pierre Aubert

Origin :Toulouse, France.

Age : 24

Watchmaking class: Fullskill

Current mood: N/A

Name: Markus McDonald.

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This week i finished the neccesary preperations for the hairspring and started the timing.

This was a lot different on a techical level being similar in nature to the vibrating but a lot more complicated as it was a digital representation of both the health and neccesary performance of the movement and naturally this required getting a hang of the feel. Through the process of elimination and adjusting I was able to gain a better understanding making it a very intresting section.

STEP 1: EPILAME! (TECHNICIAN)

We also had an interesting discussion on the various applications and policies of Epilame use on movement parts such as the escapement, winding and setting mechanism, chronograph parts etc.

STEP 2: BALANCE STAFF! (TECHNICIAN)

Oscillator with rusty balance staff! Good thing we now know how to replace them!

STEP 3: BOOKS & TOOLS! (TECHNICIAN)

STEP 4: GUIDANCE! (TECHNICIAN)

Our guide to true the hairspring around the collets.

STEP 5: STATIC POISING! (TECHNICIAN)

Static poising of a balance!

STEP 6: PINNING UP THE HAIRSPRING TO THE COLLET! (TECHNICIAN)

The parts needed to do the pinning up.

STEP 7: WINTER IS BACK! (ALL!)

STEP 8: HIGH GRADE! (ALL)

In need of a good overhaul! Amazing quality watch though!

Movement details!

Swiss silver hallmarks on the case.

Regulator index pointer with screw and locating pin!

Beast of an oscillator!

HENRIK's WORDS:

Amazing week! We

got winter back in full swing! Today (Friday) we even had -10°C freezing cold

in the morning! We finished all the

riveting, static poising and truing exercises this week and had some time to

learn how to pin up the hairsprings on the collet including practicing making

them flat and centered around the collet, certainly a delicate task when doing

it for the first time. Even though there are only two concepts/rules for correcting

flatness and the same for centering, it can still be very tricky to understand how

to make the good corrections due to that the hairspring is spiral shaped and

the correction with fine tweezers is very delicate and can easily damage the

hairspring. We will spend some good time on the hairsprings, leading us in the

direction of the really interesting timing course!

Pierre had his oral and theoretical final

examination today and next week he will do his practical, can’t believe he will

only be with us for another 2 weeks and then he is off to Holland! Markus

finished all his hairspring exercises and started the timing course; he is soon

ready to start with his trial balance/hairspring and timing exams, very happy

for him to reach that level!

Even though we were

only allowed to go 3 to visit Mr. Simonin due to the Covid situation, it was still

a great experience and we got a big bag full of books with us and even some

small hand tools for Yuriy and Willy.

Also I got a nice Patek silver cased pocket watch for an overhaul, which I used to show the difference between modern mass manufactured movements and high grade vintage movement such as that Patek, the amount of detail is a feast for our eyes! (even a lot of it is there for pride of workmanship!) Have a great weekend everyone!