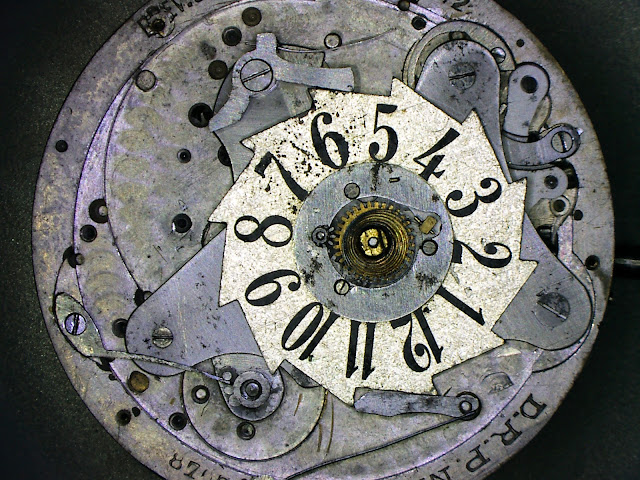

We worked on assembling and oiling winding and setting mechanism this week and today spent a day and half introducing both theory, manipulating, and oiling about barrel and mainspring. Still, the most important thing is Cleanliness and well Organized.

|

| We start practice oiling from winding and setting mechanism of 6498 and several ETA caliber such as 2824, 2892, 7750 and so on. |

|

| We clean our table everyday when we start working as a habit, and during work also try to organize ourself. |

|

| And the rest is keep practicing and make ourself fimiliar with the mechanism in different caliber. |

|

| Flatness, Straightness and cleanliness are important in watchmaking. Stan is observing the flatness of the barrel. |

|

| Always see something after oiling. In winding and setting part, we prefer more than less oiling. |

|

| This could become our Friday tradition. But we expect ourself lose as less parts as possible in the futrue. |