WEEK 164

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

This week, the technicians have been very focused on reshaping and flattening hairsprings! This unit has been quite challenging, but the work will be very rewarding once we do the timing for them.

We have also learned how to use the pivoting lathe to burnish and repair damaged/bent balance staff pivots. We quickly learned that using this tool has many pros and cons.

In addition to this, the technicians have also been working on servicing movements for their repair points. A has been working hard on a bushing for one of his movements (pictured) and Kate has been working on a vintage Omega movement with a very work intensive balance restoration.

Have a great weekend!

Lani

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, Henrik graded Tetsu’s pointed nose hand vice and Dean’s brass anvil. Both made the grade! This is a significant milestone because this concludes the completion of the graded tools, with the exception of finishing their surfaces, for which Henrik will provide instruction later in the program. In the meantime, Tetsu and Dean will continue making their non-graded, but mandatory tools.

Have a great weekend everyone!

Tetsu and Dean

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Hello everyone! This week, everybody continued the same projects as last week. Dean and Tetsuya are really close to having their tools completed. In the meantime, I’m practicing for the pivot gauge exam while Åsmund and Robert are doing the same with winding stems. David and Renato are about to start the watch technician program, so they are preparing their benches and all the tools required.See you next weekend!

Francesco.

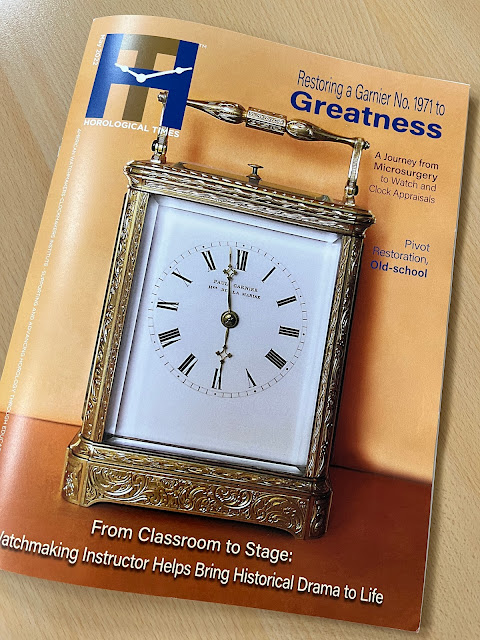

STEP 1: HOROLOGICAL TIMES! (ROBERT)

Robert wrote an article and got published by Horological Times! It is really commendable of AWCI and Horological Times to give a watchmaking student a voice!

STEP 2: TOOLS! (TETSU)

Tetsu continued with some other tool manufacturing, here drilling in the Jig-Borer!

STEP 3: BOOKS! (KHWCC LIBRARY)

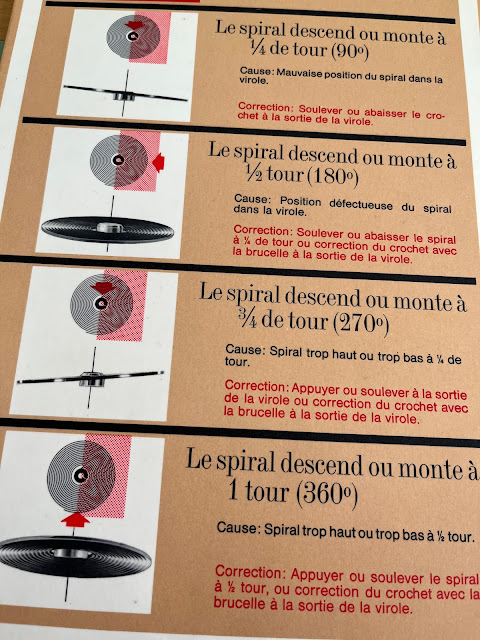

I show the technicians the book I had for adjusting hairsprings when I was a watchmaking student long time ago in Sweden, I forgot how clear and well done the illustrations were, no need even to be able to read the Swedish language as the pictures are self explanatory!

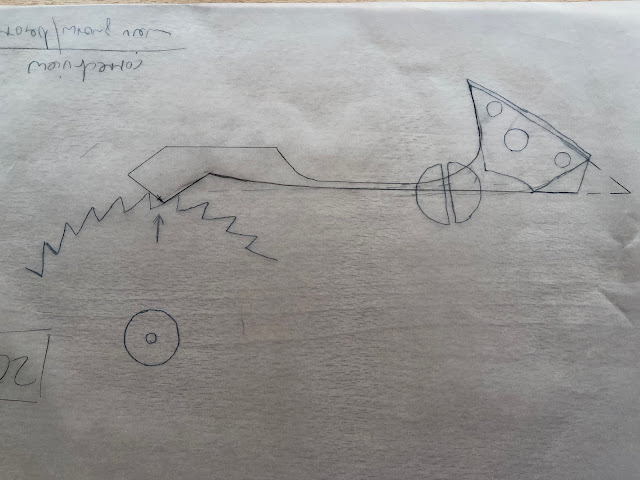

STEP 4: MINUTE JUMPER! (RENATO)

Renato designing a minute jumper for one of his pocket watch chronograph movements, it was missing altogether, only the broken screw thread was left stuck in the bridge, which he also has to later learn to extract!

STEP 5: WATCHES! (TECHNICIANS)

Even with the original timing certificate!

The technicians got some more watches to repair!

STEP 6: HANDY TOOLS! (RENATO & DAVID)

Since Renato and David started the technician course they began with making a handy checking tool that can be used to check endshakes, escapement depths among many other checking uses!

STEP 7: THREADED BUSHING! (A)

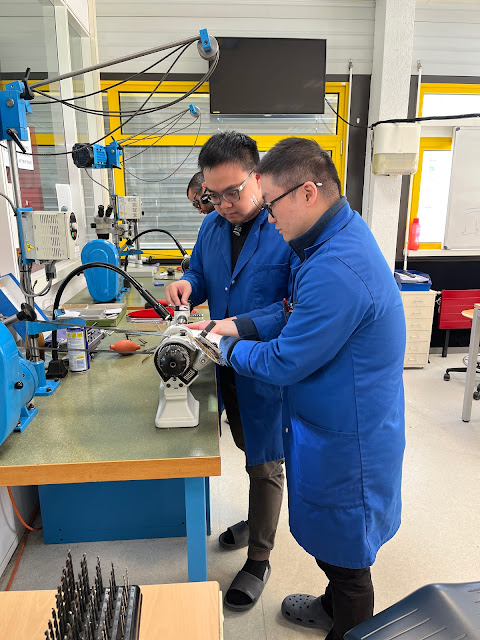

A had a vintage watch with a stripped threaded bushing that he would need to extract and make a new one for, Michael teaching how to make the bushing!

STEP 8: TOOLS! (DEAN)

Dean working on his tools, here on the Schaublin 102!

STEP 9: FANCY MACHINES! (DEAN)

Dean got this fancy and super simple to use machine (everyone got jealous) to make it faster and easier for him to extract balance staff's once he gets back to Canada to serve his customers!

STEP 10: PIVOTS! (TECHNICIANS)

Technicians checking the conditions of balance staff pivots!

HENRIK's WORDS:

It got much colder and raining off and on this week and we lost one day due to ascension on Thursday. It was also a slow pace week which is very rare for us! But also good once in a while as the technicians continue adjusting hairsprings and restoring oscillators with broken balance staffs and other problems, A also had to make a new threaded bushing for a mainplate where the threads were stripped but it was also worn out around it as it also acts as a post for a steel wheel, very interesting work as it was for a vintage watch. Renato and David started their technician course with the introduction of tweezers and screwdrivers. Its great that Horological Times published Roberts article, as it can help give a different perspective to the readers from someone who is in the beginning of their watchmaking journey, thanks to AWCI and Horological Times! Francesco and David were busy turning pivots, Dean and Tetsu completed some tools and continue on some final tools! It was a very enjoyable calm week! have a great weekend everyone!

.jpeg)

.jpeg)