WEEK 120

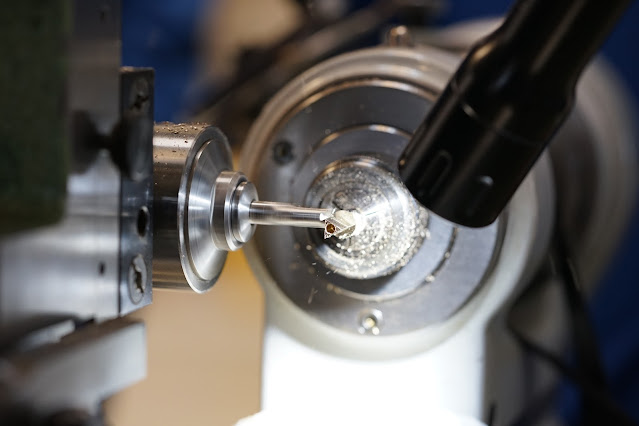

The summer finally arrived! We had really awesome weather this week, sun everyday! And also very good temperature, not too hot or cold just perfect. David had his filing exam while Renato was practicing filing squares in the 8 mm lathe with a roller support as an exercise prior to making winding stems later on. Francesco was also filing a lot, practicing filing sharp internal corners on brass to prepare for later internal corner filing for his school watch, Alex finished his tripod and black rhodium plated the base, which came out looking really beautiful! Michael learn different techniques of hand removal and installation as well as casing-up and adjusting the winding stem to correct length. Robert continued with his tool making and learn how to use the profile projector to measure angles. As a celebration for Alex finishing his final exam and also for the summer vacation starting soon we had an outing and went to Vue des Alps which was really nice! the week ended with school inventory and summer cleaning. It was a balanced and really nice week! Have a great summer and see you again in 3 weeks!

STEP1: FINISHING TOOLS! (ALEX)

Alex beautiful polishing tripod!