Last week!

The year comes to a close and the students get ready to fly back home. With the last few days before the break we are all tying loose ends and finishing up any bits of work.

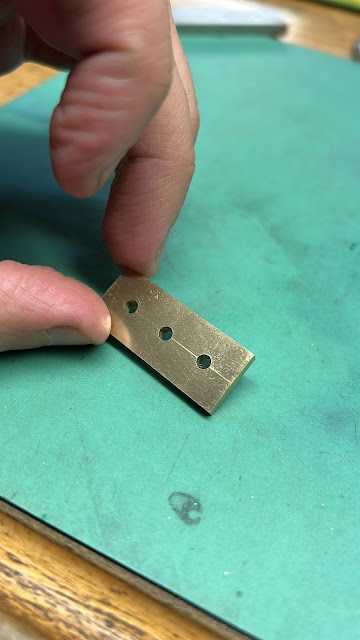

Art finished his hour wheel exam, and with Nine, they will be moving on to start their technician course next year! Craig started work on the center wheel for a 6498. This week he completed machining, filling and bevelling the wheel.

|

| Almost finished product |

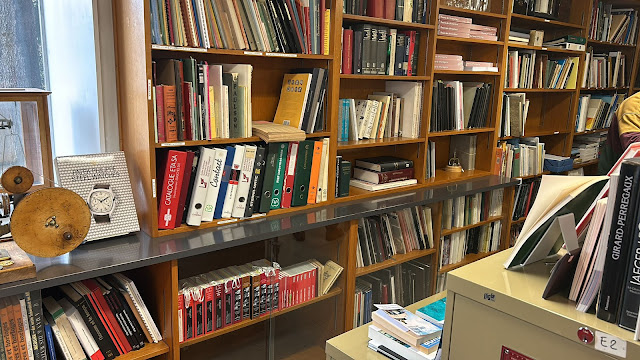

On the penultimate day we had a trip to visit a horologists in Sainte-Croix. We first had a tour of the micro-engineers at Cap14 then we got to explore the manufacturing facility of Reugue at mec-art. We were given the opportunity to listen to some of their legendary music pieces.

Stay tuned for a more in depth post coming up!

|

| Tour of Cap14 micro engineering manufacturers |

For lunch we shared several kilograms of Fondue. The hardest part of the week was leaving no cheese behind. All the students were given matching K&H bennies for the winter.

The last day was spent as every last day in K&H is spent… cleaning! From morning to evening every student does his part to leave no surface of the workshop unscrubbed. Every shelf is emptied and wiped, all machines cleaned and oiled, fridge is cleared out every corner is cleaned with the attention of a watchmaker.

|

| Final touches |

And that’s it for this year!

Have a lovely Christmas and special new years!!!

Until next time.

.jpeg)

.jpeg)

.jpeg)

.jpeg)