WEEK 170

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

Finally, we have done the hair spring exam. We learn so many things until now. The course will be finish soon and we have the last two exam left which is Theory and Final exam. Now we have to make many repair pieces to practice for a certain number of watches. Then, we will be allowed to take the Final exam. Everyone is working hard as usually and We have our own goal to be done.

A Verachai

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

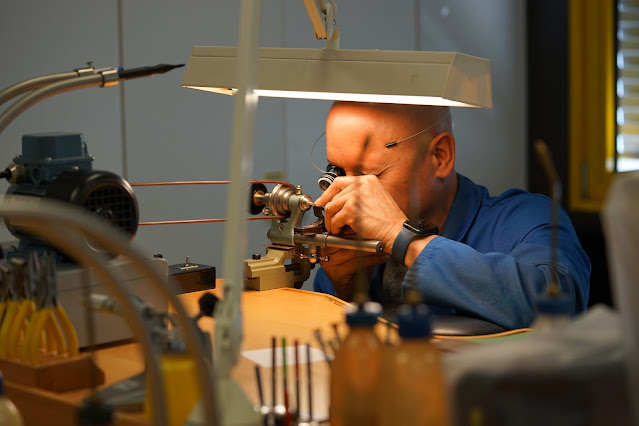

This week, (4-8 July) was Tetsu’s and Dean’s introduction to high speed steel (HSS) graver sharpening and 8 mm lathe work for hand turning. To familiarize themselves with the gravers and lathes, they worked on some brass hand-turning exercises. The development of these foundational skills will lend themselves to their ability to hand turn parts.

Henrik also introduced Tetsu and Dean to winding stems. For practice, they turned some 3 mm diameter brass pieces in preparation to file the square portions. There are several steps to making a winding stem; the filing of the square is particularly important as it is easy to file it off centre and/or in rectangular shape. Learning this skill will be invaluable during work on vintage pieces where stems are no longer available for purchase on the open market.

Have a great weekend everyone!

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

This was the week I finished all the machining on the 2 halves of the pointed-nose vice. As with other projects, there is some autonomy in how projects can be completed. I could be done with the total project of the pointed-nose vice, but shortening 2 common allen-head screws would not give me a tool I would want to look at. So...now I just need to machine 2 heads out of brass to install on threaded rods for tightening the 2 vice halves together, put some plating on all the parts, and that project is checked off.

In addition to that work, Henrik started instructions for Åsmund and I on pivot work. Never a dull moment here!

Weather has been absolutely gorgeous all week, well, Monday had a little moisture, but all other days have been very mild. We might have broken 21°C on a day or two, sun shining, birds singing, the bells of "Spot" the cow and his companions sounding in the field next to us...an idyllic Swiss week. (Especially when a project watch I ordered showed up, a thin automatic Buren micro-rotor with date...the date does not advance, the rotor rubbing on the caseback...project watch.)

STEP 1: TOOLS! (ROBERT)

Robert busy working on his pointed nose vice!

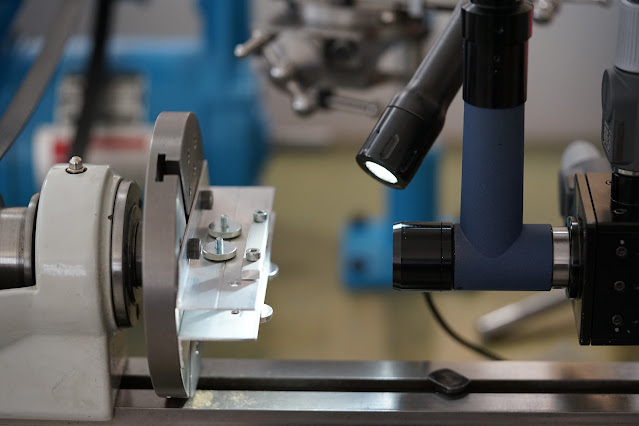

STEP 2: HAND TURNING! (TETSU & DEAN)

Tetsu and Dean practicing turning different shapes such as male cones, female cones to learn to spot the centre, conical pivots and straight pivots.

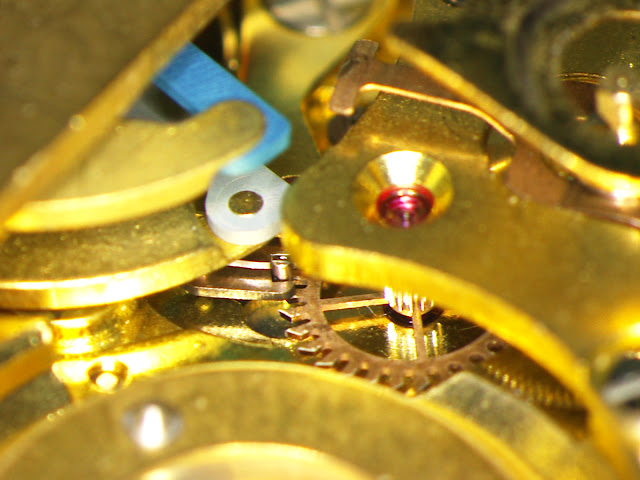

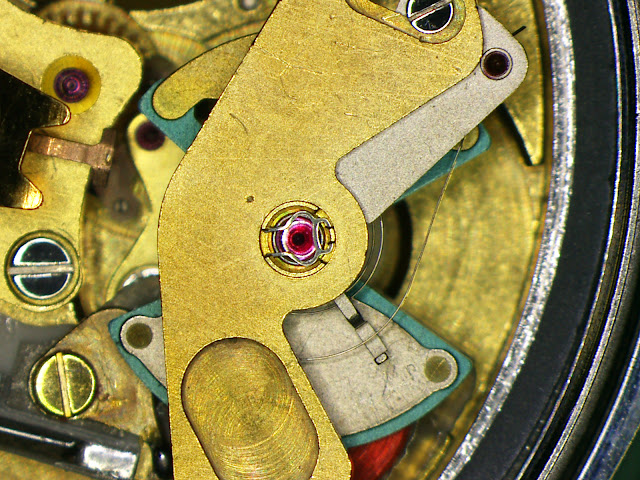

STEP 3: WATCHES! (LEILANI)

Leilani will soon service this cool looking watch!

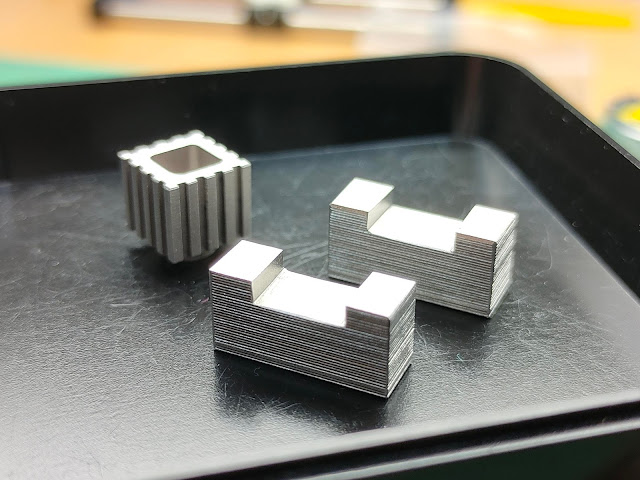

STEP 4: CUSTOM TOOLS! (DEAN)

Dean made these tools to be able to extract worn out ball bearings for the ETA 2824 oscillating weight.

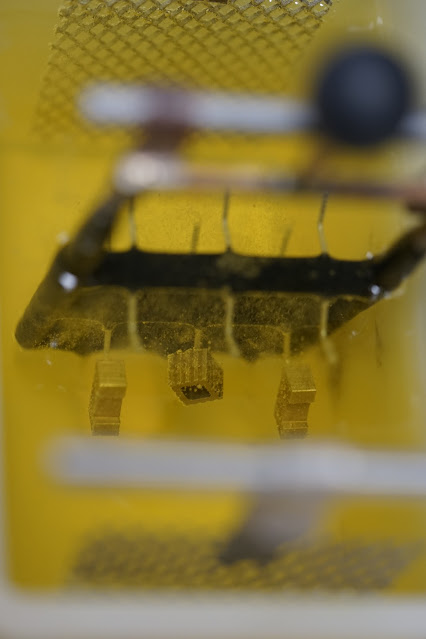

STEP 5: BLUE STEEL TURNING! (ÅSMUND)

Asmund practicing turning blue steel by hand between centres with HSS gravers, the finish is slowly getting smoother and smoother!

The weather in Le Locle got nice and sunny

and luckily not too hot! The week was very fast due to that soon we go on

summer holiday and the students want to finish as much of their exercises as

possible. The technicians finished their exam and now try to finish the last

balance and hairspring related exercises and also working on repairing complete

watches. Dean and Tetsu completed some brass hand turning exercises and next

they will practice how to file squares which is related to the later making of

winding stems. David and Renato worked on the barrel and mainspring exercise

and will also soon start to work on gear train wheels. Robert almost finished

his pointed nose vice and Francesco had his pivot gauge exam as well. It was a

very nice and also productive week! have a great weekend everyone!