WEEK 150

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

We’ve got the first pre-exam this week about the barrel and gear train. The result of the exam really shadows where we are in reality. We received comments and also the direction to correct our performance. We need to focus, revise and improve it more. Actually, it might be some pain but if there is no pain, there will be no gain.

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (14-18 Feb.) Henrik introduced Tetsu and Dean to the Aciera Milling machine. This machine is capable of the same precision as the Schaublin lathe, so to ensure it’s used to its full potential Henrik also introduced us to two measuring instruments: The dial gauge and the centring microscope. To ensure the cross slide doesn’t drift, (or drifts minimally) a dial gauge is placed in contact with it, then the cross slide is wound across it. The needle is then checked for tolerance. After using the dial gauge, the centring microscope is used to look directly down the centreline of the mill to ensure a proper setup. Fun Fact: Aciera was a Swiss company founded right here in Le Locle back in 1903, so Henrik’s mill didn’t travel far from the factory prior to becoming a part of his school’s equipment inventory.

Tetsu and Dean also took a practice filing exam. This involved the sawing and filing of two pieces; one male, and the other female. The shapes of the pieces were easy to understand, however; filing them within Henrik’s specified tolerances is no easy task. Throw in some time constraints associated with the exam and you’ve got your work cut out for you! The practice exams will be conducted at least twice prior to going live, so Tetsu and Dean will be adequately prepared for when the time comes.

Have a great weekend everyone!

Dean & Tetsu

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Hello everyone, this week I’ve finished the practice exercises for winding stems so I decided to finish my tripod.It has a different layout from the one that we have to make at school. This one is designed to clamp square pin vises. As you can see in the photos it’s a kind of vise with two screw rods at the bottom, the purpose of these screws is to adjust the hight of the tool.

A lot of machine have been involved in the project, the lathe for the two bars and the screws, the milling machine for the three brass rectangles and the drilling machine.

I largely used the pivot gauges to measure the exact diameter of the holes. The result I think is great, I got a really nice play between the steel rods and holes inside the brass block. At the end I finished the surface with the frosting technique, sablage on the big screw, black polishing on the screws in the front and straight-graining on the flanks.

At the end I’m happy with the result but I still have to finish the handle at the end of the screw rod!

See you next weekend with the tool completed!

-Francesco.

STEP 1: FOCUS! (TECHNICIANS)

The technicians working very hard to advance as much as possible in the course!

STEP 2: GRAVERS! (ROBERT)

Robert was practicing sharpening his gravers this week and got really nice results! of course these are too sharp to be practical so he will make modifications at the tip to make them last longer!

STEP 3: TOOLS! (FRANCESCO)

Francesco machining a tool!

Friction fitting!

Getting close to finish this tool!

STEP 4: MILLING! (TETSU & DEAN)

Squaring up the vice with a dial gauge!

Tetsu using the microscope to zero the spindle!

Dean counting turns to arrive at correct destination!

Flying chips!

STEP 5: PHOTOGRAPHY! (FRANCESCO)

Francesco taking photos of his practice squares!

Francesco also finished his square filing exercises!

STEP 6: OVERHAULING! (RENATO)

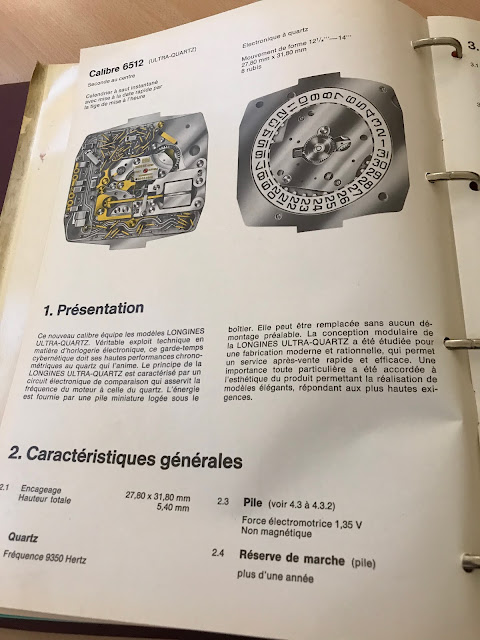

Renatos Ultra Quartz Longines watch was overhauled and a reduction of 20% consumption was achieved and its now within the normal specs for this calibre!

STEP 7: EXAMS! (TECHNICIANS)

The technicians ready for their first trial exam!

STEP 8: PIVOTS! (RENATO)

0.17 mm pivot gauge!

Renato made another couple of very nice pivot gauges this week, this is the 0.17 mm!

STEP 9: BOOKS! (RENATO)

Another really interesting book on loan from Renato!

STEP 10: BIGGEST BASE IN SCHOOL! (FRANCESCO)

Francesco was very lucky to get this gem of a measuring tool base! A bit bigger than a regular one ;)

HENRIK's WORDS:

Its getting considerably warmer in Le

Locle, instead of snow we mainly now get rain and the snow is almost gone! After

overhauling Renatos Longines Ultra Quartz, the consumption got down by as much

as 20% and is now within the expected norm for this calibre, this was nice to

see as we had no clue if it would improve or not! We also had two different trial

exams this week one was for the technicians, their first exam covering the

winding, setting, barrel and mainspring, and the gear train with its jewelled

bearings and the other trial was for Dean and Tetsu, their first

micromechanical trial exam, filing and sawing brass by hand. Francesco finished

a series of hand filed squares in brass as a first practice ahead of winding

stems. Renato finished another couple of pivot gauges, very fast and good

quality! Robert practiced sharpening his HSS lathe gravers by hand, very high

quality! A very friendly local gave a good deal to Francesco on a very

impressive vertical measuring stand that can be used with micrometres and

comparators as they usually have the same standardised shaft diameters! A

balanced but also very intensive week! Have a great weekend everyone!