WEEK 132

Michael

Origin : Malaysia

Watchmaking class: Technician & Fullskill

Current mood: Finally finished my final exams last week! This is the finishing week and lots of fun stuff to do! First time doing flanks and bevels. Very addictive! Just don’t know when to stop. We were introduced to the various finishing including Geneva stripes, frosting, Matt finishing and etc. Looking forward to next week to meet new people attending the finishing class for public. Have a great weekend everyone! Cheers!

Renato & David

Origin: Zug, Zürich, Switzerland

Watchmaking class: Fullskill

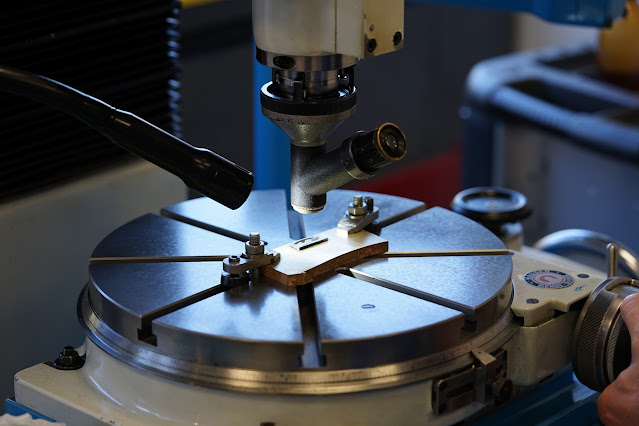

Current mood: This week we learned different finishing techniques. We learned how to do Geneva stripes on the milling machine, frosting, straight graining. We tried bevelling and refinishing the flanks of different parts. We learned how to finish countersinks. David

This week was finishing week. We started with black polishing screws. Interesting to see all the finishing tools that can be used on various parts of the movement. Abrasive papers, polishing paste, various materials/shapes they can be applied on... lots of possibilities we explored. Sablage, frosting, Geneva stripes, straight graining... check. Week ended with working on a yoke on which we also practiced bevelling and polishing the bevels by hand and with a motor. Not done yet, but it was great to try several techniques to figure what works best for me. Renato

Francesco, Åsmund & Robert

Origin: Italy, Norway, USA

Watchmaking class: Fullskill

Current mood:

Hello,

This week was very exciting. We have learned many different finishing techniques, black polishing, bevelling, make counter sinks, frosting, matt finish on steel and Geneva stripes. and even more to come next week as well.

Spent most of the week experiencing with black polishing screws, bevelling and polishing a yoke. Preparation are key to perfection

Have a great weekend.

-Å

Hi everybody,

this week was really intense because of the finishing course. We had a lot of lessons: we started with the black polishing technique and I polished screws and a crown wheel. Then Henrik showed us how to finish flanks, counter-sinks and some different techniques to make bevels. At the end of the week we learned to make steel matt looking, Geneva stripes at the milling machine and frosting with two powders.

I have just started finishing a yoke lever from the ETA 6498. I have finished the flanks and I’m going to begin with hand bevelling.

Have a nice weekend,

Francesco.

This week all prior projects were set aside while we received instruction on applying various methods of finishing (decoration) to watch movements.

Bevelling edges of parts, machining Geneva stripes, and other methods of finishing large, flat surfaces were the main focus.

Some time was also spent on tool-making to hold some of the smaller parts while they had the finishing work done to them.

Not much else to report on, as this week was heavy on the "Instruction & Demonstration" part of this watchmaking pursuit.

Robert

STEP 1: FINISHING WEEK! (ALL)

Everyone busy with practicing various finishing techniques!

STEP 2: WATCHES! (RENATO)

Renato show us one of his cool wristwatches! Not sure we can really trust all the values due to the quartz's crystal running at warp speed, 2.4MHz!

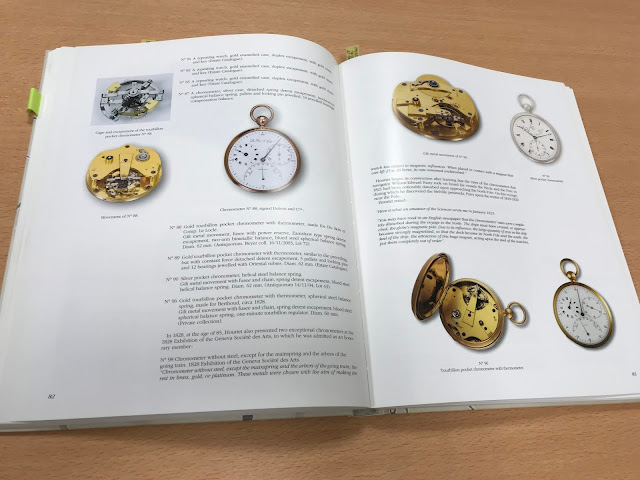

STEP 3: BOOKS! (KHWCC LIBRARY)

This is a very enjoyable read! especially since it describes a lot of the life of the company and the people behind the chronometers as well as having some repair tips concerning marine chronometers.

HENRIK's WORDS:

As I suspected this week did get extremely busy! I introduced everyone to common classical finishing techniques such as Geneva stripes, making steel parts matt and black polished, Frosting on brass bridges with polished and bevelled countersinks etc. Since it was only a short introduction they will continue practicing next week and hopefully soon we have some nice finished parts to show you! This part in the course is always very exciting for everyone! And it continues next week with another 3 watchmakers coming for a similar finishing week as well. Very nice week! have a great weekend everyone!