WEEK 84

Willy, Yuriy, Alex, Michael

Origin : Singapore, Canada, Taiwan, Malaysia

Age: n. a.

Watchmaking class: Technician & Fullskill

Current mood: A very busy and interesting week for all of

us. We were Introduced to the theory of the barrel and mainspring. Henrik

taught us how to dissembled and assemble the barrel and fully service the

barrel including checking the side shake, end shake, freedom of the barrel,

hand wind the mainsprings or the more sophisticated way by using the winding

tool as well. We have to oil the arbor and mainspring before closing the cover.

Also put breaking grease for automatics. Last but not least also check for the

power reserve as well! Looking forward to next week! Have a good weekend

everyone!

Pierre Aubert

Origin :Toulouse, France.

Age : 24

Watchmaking class: Fullskill

Current mood: Now onto making the last functional sections of the barrel! The first one is to make the recess for the sliding pinion and winding pinion. Part of it includes two steps under the barrel bridge to provide clearance for the winding stem as well as the shoulder of the setting lever screw. In fact, the bridge wouldn’t go down without the latter.

In that regard I first designed the recesses and drew the steps accordingly before scribing these areas on the jigborer. I then went and milled these two steps at their respective height. Next: milling the recesses.It’s exciting to see this barrel bridge nearing completion..! Not yet there but enjoying the process! Don’t want to think about the future, I’d rather be focused on these present tasks. Anyway, have a great weekend everyone. See you next week.PS: Getting cold here, I quite like it. I hope we’ll get snow this year..!

Name: Markus McDonald.

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This is week was spent working on various projects and finishing parts of the movements in preparation for next week being the start of the hairspring. For the balance and escape wheel section it was a lot of fun getting to further expand my escapement knowledge and theory.

In conclusion working on this segment was a great experience and I am looking forward to starting the new module.

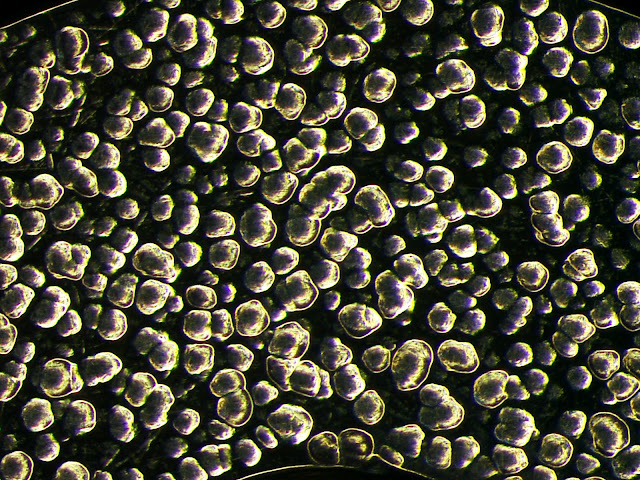

STEP 1: ZODIAC! (YURIY)

Yuriy brought one amazing Zodiac watch with him that he will later service. Notice the blue jewels!

STEP 2: ENERGY ACCUMULATOR! (TECHNICIAN COURSE)

We also had a look at some very old energy accumulator systems, here is an old 8 day barrel.

Sometimes they explode! This one was even bound up by iron wire.

Or should we...

Special shape mainspring!

Fusée and the chain!

Type of flying barrel pivoted at one end only.

STEP 3: BARREL CLOSING TOOL! (TECHNICIANS)

Modern barrel and mainspring with student own made barrel closing tool! (black).

HENRIK's

WORDS:

This week was very fast! The Technicians

learn to service the energy accumulator of the mechanical watch called the

barrel and mainspring, this went very well, they learn for example the quality control

of the relevant components, side-shake and end-shakes, installation by hand and

with professional tools, cleaning and lubrication. Yuriy also learn the basics

of turning with the Schaublin 70, ending the week with his own made barrel

closing tool. I was completely busy with giving demonstrations, theory lessons

and checking student work and got no time for anything special, except for

having a great talk with Jason at AWCI, we are going to collaborate on something

exciting regarding watchmaking education, most likely around January and February next year,

this may be interesting for watchmakers all around the world! I will of course

notify when we get closer to the date. Have a great weekend everyone!