This week we had another bench tester! Sheikh Ibrahim from Singapore!

|

Here he is assembling a 6498!

|

STUDENT HIGHLIGHTS

Workshop A

Students:

Amer, Dunham, Daniel, David, Harold, Miguel

This week Daniel, David and Miguel continued working on oiling the winding and setting of their 7 movements and also learned how to clean and oil the barrel of manual and automatic watches.

Daniel has been finding the best size for a minute wheel restoration, unfortunately the current wheel just a bit too big.

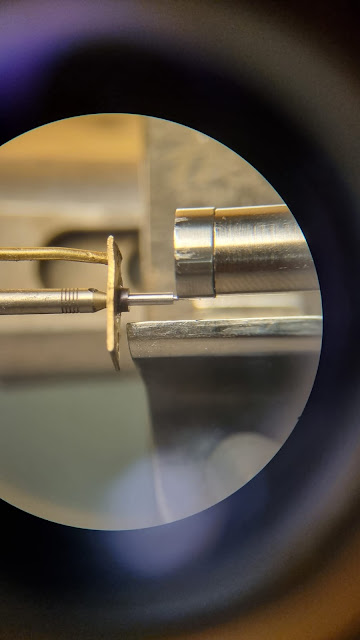

Daniel also needed to make custom Horia pushers for a bridge restoration.

|

The new pusher

|

|

New minute wheel in brass

|

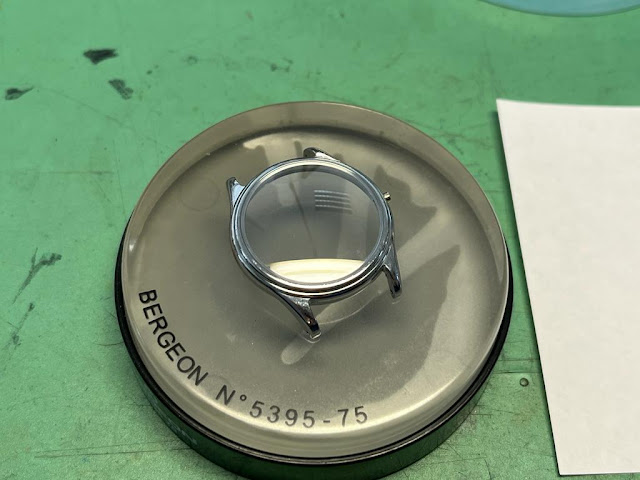

This week Miguel also finished his barrel closing tool.

|

It is larger than the standard tool from Bergeon to accomodate larger watch barrels.

|

|

| It was also polished to be more transparent than the standard so you could see the barrel you are working on. |

|

|

Here you can see a barrel that is being oiled.

|

|

The tool is clear enough that you can see the drops of oil for lubricating from the top.

|

This week Harold redid and reviewed the disassembly, cleaning and assembly of three types of Incablocs, practiced on how to fix mislocking, and worked on the movements.

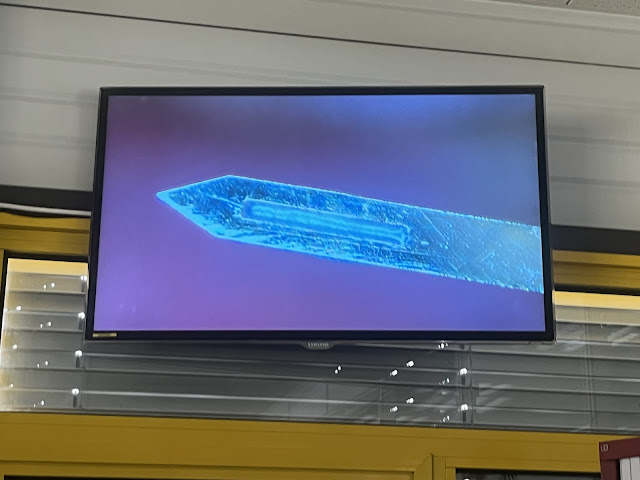

This week Dunny was very busy! He finished his Steel angle rule, polishing tripod, and pointed nose vise ready for finishing, serviced his 8mm lathe, sharpened 4 gravers and started hand turning.

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)