WEEK 95

Willy, Yuriy, Alex, Michael

Origin : Singapore, Canada, Taiwan, Malaysia

Age: n. a.

Watchmaking class: Technician & Fullskill

Current mood: It has been another busy week. Had many theory lessons as well as exercises. Applying shellac is especially fun once you get a hang of it. Adjusting end-shake is also kind of fun. Looking forward to next week where we learn how to move the position of the pallet jewel.

Pierre Aubert

Origin :Toulouse, France.

Age : 24

Watchmaking class: Fullskill

Current mood: « In »s week: both interesting and intense as I finished my first hand turned balance staff and made my first hour wheel in prep. for next week’s exam! Will be able to get back to some school watch work (hopefully) after that.

Need some rest...! Have a great weekend everyone.

Name: Markus McDonald.

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This week I focused on two sections. Completing the finishing on some tools and projects and resuming the hairspring course.

Both of these went well being able to add finish to my tools such as frosting, straight graining and plating was hugely satisfying. Resuming the hairspring section went well initially starting as a warm up but getting back into the routine was both a nice change of pace and satisfying.

STEP 1: WHEEL MAKING! (PIERRE)

Setting up the machine for cutting an hour wheel for the ETA 6498.

Centering cutter.

Milled teeth, wheel is now ready for parting and finishing.

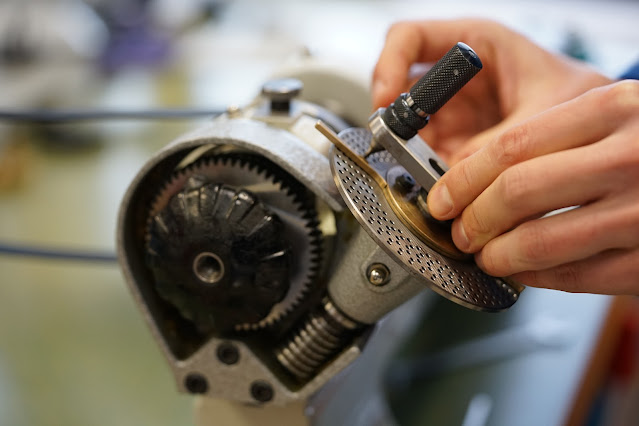

STEP 2: DIVIDING HEAD! (PIERRE)

Pierre also learn how the dividing head works before milling the wheel, here a demonstration how to change the disc to have the right divisions (number of teeth on wheel).

Ready to install the correct disc.

STEP 3: SHELLAC! (TECHNICIAN)

Melting the shellac on a piece of tracing paper, probably baking paper will also work.

Breaking it into flakes.

Each student got their own lifetime supply of shellac.

One practice pallet with applied shellac.

STEP 4: BALANCE STAFF! (PIERRE)

Pierres balance staff turned by hand between centres in the Horia lathe and burnished pivots also in a Horia Jacot tool ready to be riveted on the balance.

Comparing the size of Pierres balance staff on a 10 cent Swiss coin.

HENRIK's WORDS:

Very busy week! The technicians learned more about the escapement theory and tried out shellacing which is basically just a natural resin produced by an insect used as holding the pallets in place like a natural glue, this can sometimes be a bit tricky to learn, but very fun! Pierre learned how the dividing head on the Schaublin works and how to mill a wheel in the lathe, specifically the 6498 hour wheel, he will next week have his exam on it. Pierre also finished his first ever balance staff and I was surprised to see it in such good condition, although its not perfect its still impressive that he got good dimensions and did not break the delicate pivots and most importantly its functional! It was turned between centers in the Horia lathe. Markus learned different finishing techniques as well as how to gold plate. Have a great weekend everyone!