WEEK 130

Michael

Origin : Malaysia

Watchmaking class: Technician & Fullskill

Current mood: n/a

Renato & David

Origin: Zug, Zürich, Switzerland

Watchmaking class: Fullskill

Current mood: Polished the winding stem for the vintage chrono pocket watch movement that I made last week. Big cylinders I had to do between centers. Interesting construction with a brass piece glued to the stem for motor attachment. Worked absolutely fine. Quality of the polish was not as good as the last time, but that's only visible at certain angles. Need to check the piece perpendicular to its axis next time as well. Spent a whole day on preparing all the 15 gravers I have, to be ready for winding stem practice exam(s) next week. Also disassembled the pocket watch chronograph movement that I already made a prototype brass winding stem for. The setting lever was broken. Designing it will be the next thing besides practice exams next week. Looking forward to it! Renato

This week I worked on creating a winding stem. Unfortunately during the end of the process it broke. Better luck for me next week, when I will make a new one. David

Francesco, Åsmund & Robert

Origin: Italy, Norway, USA

Watchmaking class: Fullskill

Current mood: Not a lot of activity to report, as a lot of time went into writing up steps and procedures for milling a tool in the Aciera F1 mill. The tool looks deceptively easy, but as one writes up the steps to do the milling, it brings up other steps and procedures to consider.

To cut the opening to the right size, do you figure in the small amount of backlash, or do you spend the time to raise the cutter, go back to a "Zero" datum point, move the cutter over for a fresh cut, then dial the cutter down into the hole to the correct depth again...and again...

Had more gorgeous fall weather this week. With any luck, we may see more.

Robert

Hello everyone,

This week I spent most of the time on the shaublin 70, making buttons for the pressfit exercise. Made 3 different buttons, one flat, one with outward angle of about 26° and one with inward angle with the same degree. The inward angle are done with a handheld graver, so this took a few tries before I got the flatness and finish right. These are supposed to fit perfect into each other as you are going to use one to press the other into a brass plate.

The rest of the week I’ve been making another 1mm brassplate with two 45° Internal corners. The first one turned out good, but I want to improve it as it is a quite fun challenge to do.

Have a good weekend

-Å

STEP 1: TESTING! (CLIENT)

Michael sent the prototype pinion to the client who tested it in the compressor case, it was working perfectly!

STEP 2: FINISHING A WINDING STEM! (RENATO)

STEP 3: OUT OF RANGE! (FRANCESCO)

Francesco looking for a solution to mill his scissor style balance wheel support, unfortunately his piece was too long for the Aciera F1 so he needs to find another solution!

STEP 4: WINDING STEMS! (DAVID)

STEP 5: BOOKS! (KHWCC LIBRARY)

STEP 6: TURNING! (ÅSMUND)

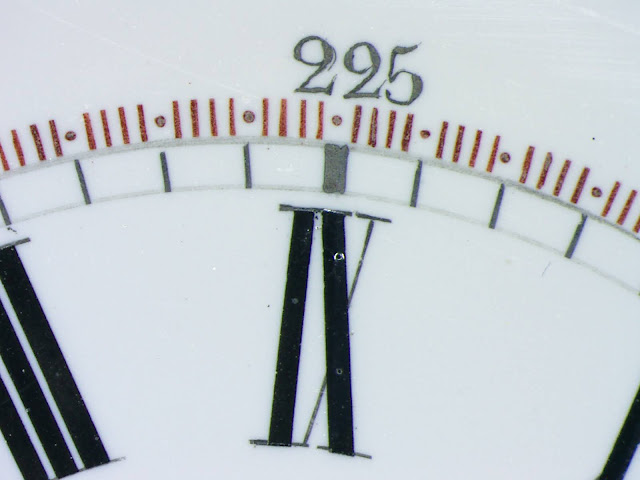

STEP 7: DISASSEMBLY! (RENATO)

This movement needed a new setting lever to be made for it, and to reach the broken one he needed to disassemble the movement!

Partially disassembled!

Partially disassembled!

Organized and ready to be restored!

STEP 8: WATCHES! (RENATO)

HENRIK's

WORDS:

Nice

sunny week! Michael started his final exam which will end next week.

Renato finished another one of his pocket watch winding stems and had to

disassemble one of the movements to reach the setting lever which was broken

and a new one needs to be made. David started to practice making complete

winding stems, Francesco and Asmund continued on their tool manufacturing.

Robert was working on the milling machine to work on some of his tools as well,

otherwise there was nothing new this week, it was a nice balanced week though! Have

a great weekend everyone!

No comments:

Post a Comment