Week 8

This week we had another bench test! Nicholas from England!

|

| Here he is learning how to put in the mainspring in the barrel by hand. |

STUDENT HIGHLIGHTS

Workshop B

Students:

Amer, Dunham, Faris, Ivan, Louis, Varun

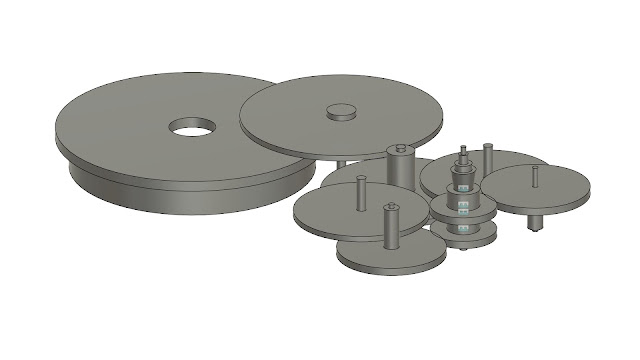

This week Ivan continued planning out his school watch with Fusion 360.

Ivan also continued his restoration work on his pocket watch. |

| He beveled and polished the edges of the ratchet wheel and used tetrabore to matt finish the top of the screw. |

.jpeg) |

| Here Ivan refinished the entire surface of the barrel bridge. He used paper to flatten the surface before he frosted the surface. |

GUEST STARRING

Workshop A

Students:

Art, Daniel, David, Harold, Miguel, Nine

This week Daniel, David and Miguel learned how to oil the gear train and apply epilame.

|

| Coming in at a 45º angle to touch the pivot to allow oil in. |

|

| Using a dropper to apply epilame only to the teeth of the escape wheel. |

|

| 2 Incabloc jewels. The one above has epilame and the bottom does not. You can see that the epilame helps the oil to form more consistently for cleaner work. |

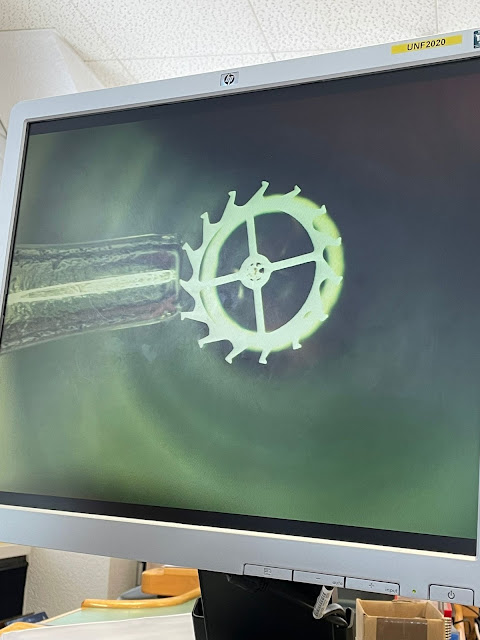

This week Daniel made a prototype of his escape wheel and asked Ivan to help him create his gear train in Fusion 360.

|

| Daniel made some mistakes centering the spokes and wants to reshape them to be thinner. |

This week Daniel also prepared to take his escapement exam next week

This week David and Miguel took their escapement exams and passed!

This week David also serviced his Omega 601.

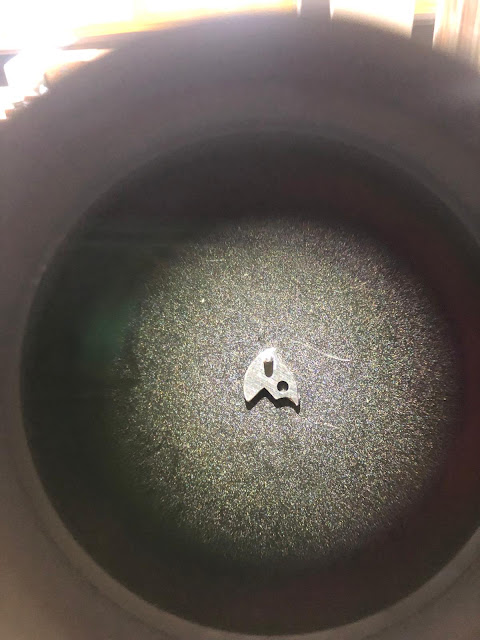

This week Miguel made and finished his pallet fork holder just in time for his escapement exam.

The base is made out of brass that has been straight grained and black rhodium plated before the mandrin was cut down and friction fit into the base. It was designed to be adjustable when under the microscope to check the cleanliness of the pallet fork.

COMING UP NEXT...

We have another bench test next week! Tune in next week to find out where they're from.

Thank you for reading!

Hope to see you again next week!

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)