This week we're moving to work on the hairspring and keep poising the balance.

After the balance staff has been riveted to the balance, we need to make static poising to make the balance balanced.

Meanwhile, starting the new course of hairspring, from removing the stud and collet on old hairsprings, then put them back together with new brass pins as a pre-exercice before working on new material.

Now the thing got so delicate, so we really need to hold our breath when adjusting it.

|

| lots of hairsprings to work on! |

|

| Stan is poising the balance. |

|

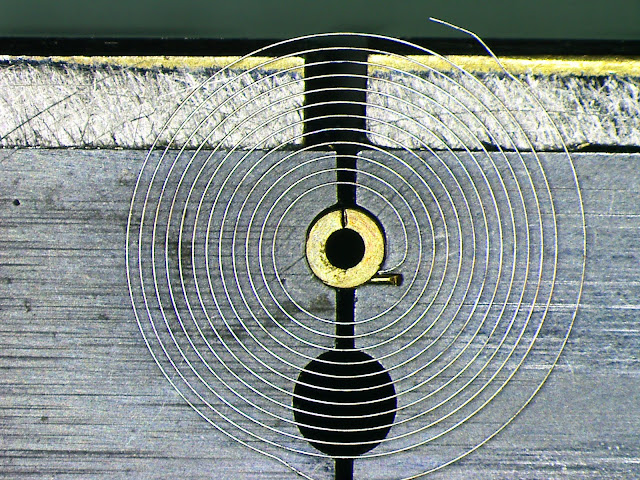

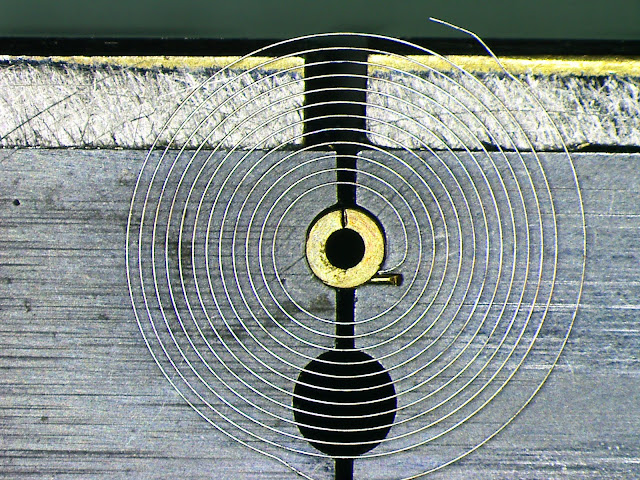

| Now we're working more under the microscope. |

|

| Cheking the pivot before poising. |

|

| Before removing the stud. |

|

| After. |

|

| The collet for holding the hairspring. |

|

| Also remove it. |