WEEK 79

Pierre Aubert

Origin :Toulouse, France.

Age : 24

Watchmaking class: Fullskill

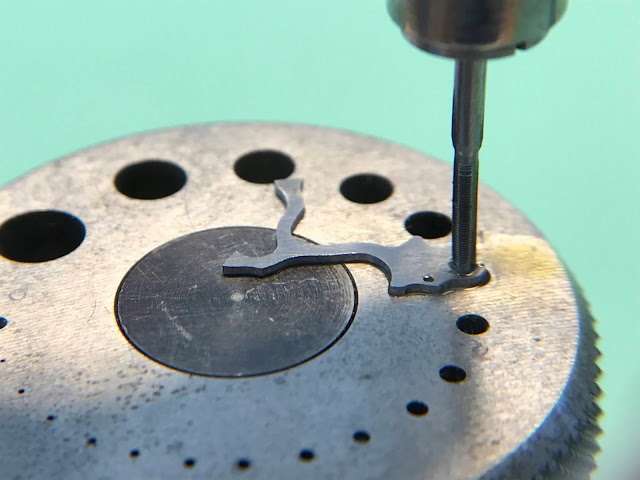

Current mood: Getting there! I made mock-up pins so that I can drill the holes I left to be drilled for later. In fact, if not precisely located with pins, the holes won’t be aligned with the main plate holes. I will later make some nice locating pins, but for now those are enough as I am only worried about function! Also glad that Autumn has really settled in Le Locle :) It’s time for comfort food. Have a good weekend everyone! See you next week :)

Name: Markus McDonald.

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This week I continued with the escape section covering both practical and theory.

The theory went well covering a bit every morning being centered around the fundamentals of the Swiss level escapement. This was super interesting learning the different rules and variables that allows the movement to function from a theoretical level.

It also helped to put the escapement into perspective in regards to the history of watch making how we went from great grandfather clocks to simple yet functional wrist watches and how the foundamentals of those old clocks had carried on being relevant.

This applied greatly to the practical angle of the escapement how one would adjust the regulating organ and it’s importance. In conclusion this week went well, being quiet varied in what we covered allowing for a good mix of practical and theory this allowed for it to be both interesting and stimulating.

Origin : Malaysia

Age : 28

Watchmaking class : 2 years Fullskill Program

Current Mood: Finally! Scored my pivot gauge exam. Happy

man. I also made a wooden mallet for future centering purposes. Looking forward

to next week which is the individual week to make the mandatory pivot gauges

ranges from 0.07-0.20mm and some tools.

Alex

Origin : Kaohsiung, Taiwan

Age : 27

Watchmaking : 2Y Fullskill Program

Current mood: Finally! Scored my pivot gauge exam. Happy

man. I also made a wooden mallet for future centering purposes. Looking forward

to next week which is the individual week to make the mandatory pivot gauges

ranges from 0.07-0.20mm and some tools.

STEP 1: WINDING STEM! (ALEX)

Alex winding stems getting black polished!

STEP 2: SCHOOL WATCH! (PIERRE)

Pierre fitted trial locating pins for his bridges

Testing the bridges on the mainplate with the locating pins.

STEP 3: WOODEN CENTRING HAMMER! (MICHAEL)

Head to be customized later.

HENRIK's WORDS:

Another very diverse week for me, lots of

escapement theory and demonstrations. Markus reached a very interesting part of

the escapement course and is doing very well. Alex and Michael continue with

micromechanics and also made their own wooden hammers probably got inspired by

Pierre who used it when centring parts in the lathe. Pierre continues to progress

very well with his school watch. Next week will be a very intensive and interesting one since I

will ones again run the Chronograph course, and also one more Technician will join

the team! Have a great weekend everyone!