WEEK 141

Friday, December 17, 2021

HOLIDAY!

Friday, December 10, 2021

STOP WORK!

WEEK 140

Asmund was busy finishing some of his tools and also practiced more snailing, here he is setting up the milling head on the cross slide of the lathe before starting the finishing!

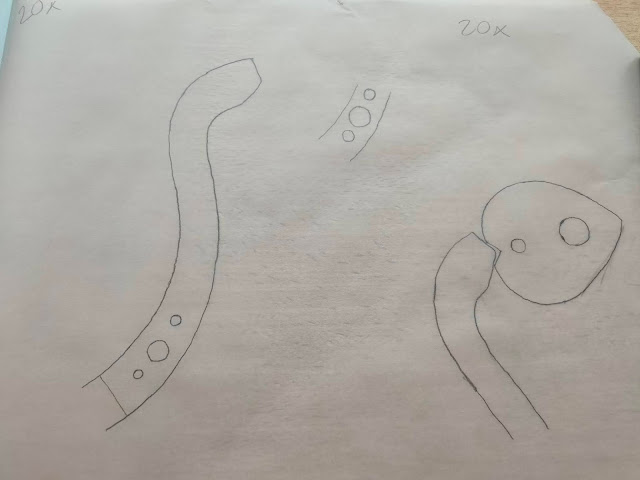

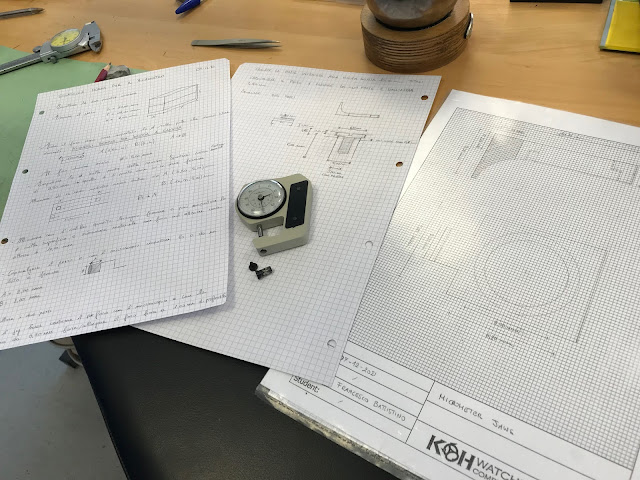

He made some instructions and drawings for his jaw making!

HENRIK's WORDS:

We got massive amounts of more snow and forecasted even more in the next few days! Very busy workshops which is not surprising this close to Christmas, everyone wants to finish as much as possible before the holidays! As so many other previous weeks this one was also very diverse and interesting. Renato finalized his Maltese cross in steel and it worked perfectly! He will do the finish at a later stage in the course when he has manufactured some more watch parts, David continued practicing making winding stems and did two winding stem trial exams, Michael continued designing and drawing parts for his school watch project, Robert and Francesco continued with tools as well as making more suitable measuring jaws for a small micrometre they got. Asmund also tried some more ground snailing on his barrel including red gold plate it. Tomorrow we will go to Herrli in Bienne to get some more tools! Have a great weekend everyone!

Friday, December 3, 2021

COOKIES!

WEEK 139

Asmund practiced finishing ratchet and crown wheels, this is one of the practice wheels, the pictures above is the same wheel but under different lighting conditions!

HENRIK's WORDS:

As forecasted we did get plenty of snow and this time it sticks around as the temperature got lower! Nothing much new this week except Asmund tried out grinding a snailed finish on ratchet and crown wheels. As we have not done anything together for sometime we decided to try to make our own cookies as many of us have it for the coffee break anyway, I think we got enough cookies to last us until next year probably! David continued practicing making winding stems, Asmund, Francesco and Robert continued with their tools and Michael continued designing parts for his school watch project but now with the computer program Inventor from Autodesk! It was a nice week in general! Have a great weekend everyone!