This week, (25-29 September) Tetsu and Dean worked on some outstanding tasks and projects.

Tetsu finished the last of his seven movements, then went straight to work on hand-turning a balance staff, which was completed on Thursday. These were two significant milestones in the Fullskill program, congratulations!

From the chronograph course, Dean overhauled an ETA 2894-2 movement. The chronograph module was challenging as it has a number of springs and only one bridge to hold them down.

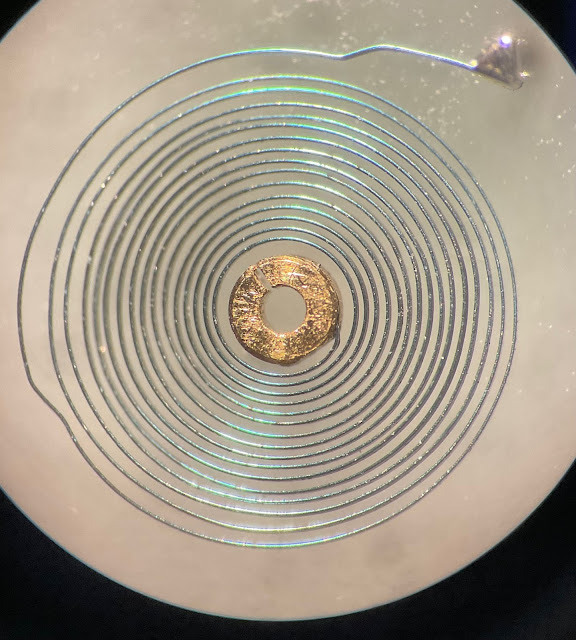

Dean also worked on a vintage Rolex 1520 movement, in particular the hairspring and barrel bridge. The hairspring was quite bent, so it took a bit of time to straighten it out.

A worn barrel arbour hole on the barrel bridge was causing the barrel to lean over far enough to contact the bridge, so Dean drilled out the hole and installed a bushing.

|

| Slot cutting practice pieces compared to a 1 Euro coin. |

GUEST STARRING

Workshop A

Students:

Amer, Dunham, Daniel, David, Harold, Miguel

This week Harold did two practice exams and one trial exam, all of which were on winding & setting system lubrication, flattening of wheels, barrel disassembly, lubrication, assembly and adjustment, and adjustment of gear train.

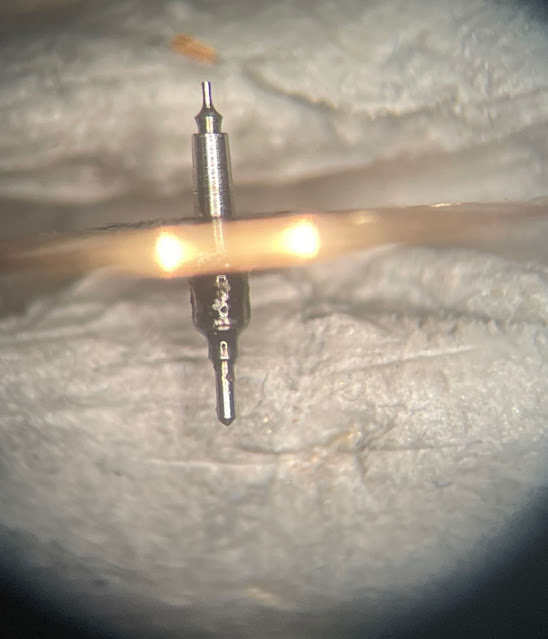

This week David started learning how to make a balance staff.

Miguel finished making several pivot gauges. He finished the sizes 0.18 to 0.14.

This week Amer and Dunny took their hairspring exam. Amer also finished his 7750 chronograph adjustments.

.jpeg)

.jpeg)

.jpeg)

No comments:

Post a Comment