Week 37

This week It was Ivan's birthday!

We also had a surprise visitor, Francesco! He stopped by after work to say hello and pick up a few things.

Henrik also received a very kind donation of old watch parts, materials, and watch movements and will use them one way or the other for education.

These parts were very kindly donated by Mr. Anthony G. Randall. A watchmaker who has done much in the field of restoration, production, and design of watch movements.

You can read more about him from this article: https://www.watchonista.com/articles/history/prix-gaia-2003-anthony-g-randall-craftsmanship-creation-category

STUDENT HIGHLIGHTS

Workshop B

Students:

Dean, Faris, Ivan, Louis, Tetsu, Varun

This week, Henrik introduced Dean & Tetsu to another chronograph; the 2894-2. This will be a long term project, starting with timing of the movements under varying conditions, including 50-hour trace measurements, so that we will be able to compare performance before and after movement overhauls.

While running the 2894 on the timing machine, the guys continued working hard on the remainder of the mandatory 7 movements and watches for service repair points.

We had wonderful weather till Tuesday, but it seems like that the climate finally decided to go towards autumn.

This week, Ivan, Louis and Varun learned how to service the 8mm lathe in preparation for learning how to make winding stems.

GUEST STARRING

Workshop A

Students:

Daniel, David, Harold, Miguel

Miguel took several practice exams for pivot gauges.

This week David restored the reverse cone of his between centers lathe.

|

| Between centers lathe with the reverse cone to seat the workpiece. |

.jpeg) |

| Destroyed female cone which causes the workpiece to wobble and be off center. |

|

| Restored cone after turning on the Schaublin 70. |

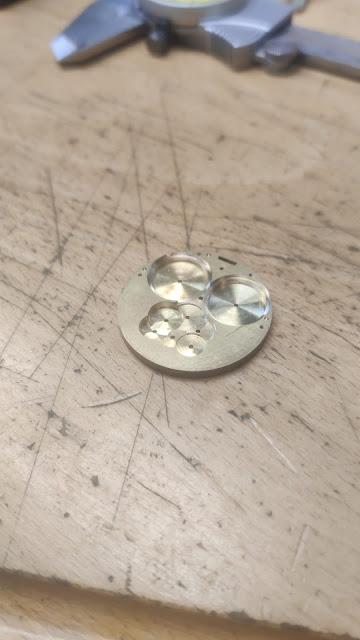

This week Daniel has started to do prototyping for his school watch project, with the fundamental of the mainplate and barrel bridge taking shape.

|

| Main plate in brass with the spots for the gear train milled down. |

|

| Barrel bridge with the recesses for the barrels and ratchet wheel. |

This week Miguel also learned how to use the spotting machine to make perlage. He experimented with it on his pointed nose hand vice.

The initial finishing of straight graining. .jpeg)

The two finished pieces.

(Right) The second piece has diagonal rows of 2 overlapping layers.

Thank you for reading!

See you next week!

.jpeg)

No comments:

Post a Comment