WEEK 177

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

The Final exam is coming soon. We are preparing to it. But this week, we also had a relax outing day and visiting Simonin books store.

Technicians are busy with the last trial exam and next week is the last week of the learning and preparation for the exam. Hope it will be ok for all of us.

A

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, Tetsu and Dean continued working on their winding stems; this time, in steel, which is more time-consuming than brass, but allows for not too much material to be removed during graver operations. Henrik introduced Tetsu and Dean to heat treatment, involving the process of hardening and tempering. This provided its own set of challenges, including ensuring that the winding stem is heated enough to harden the steel. The tempering process requires the piece to be heated to a temperature over a period of time adequate enough to evenly heat the piece throughout, bringing it to a blue colour before it is removed from the heat.

Have a great weekend everyone!

Tetsu and Dean

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Robert-

My week was all about making pivot gauges. They are used to measure (gauge) the holes in the jewels of a watch. These are perhaps some of the most time-consuming projects per piece so far, and all I have are bad examples. Just a little too much pressure, and they will break before being finished. See Åsmund's good example.

This Friday was also a visit to Mr. Simonin's bookstore. We got some books, some tools, and listened to Mr. Simonin explain the history of some watches.

Åsmund-

This week was pivot gauges, too. See the picture of the example Robert mentioned.

Francesco-

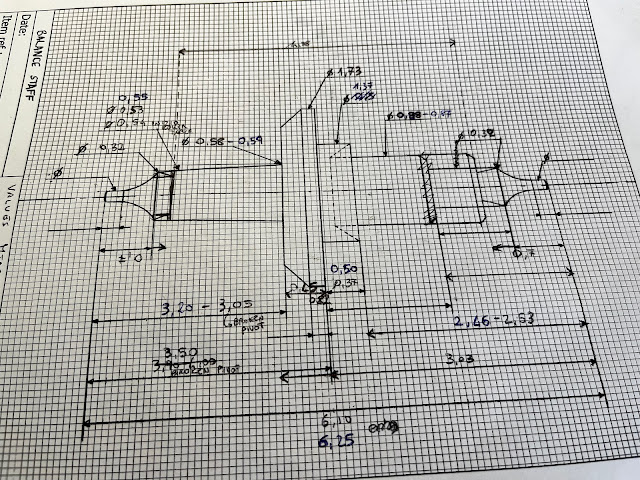

This was a project week, working on a balance staff for an old English lever pocket watch.

STEP 1: FIRE! (DEAN & TETSU)

Heating the winding stem before dunking into saline!

First Dean and Tetsu made cocoons to keep the winding stems in with a handle to quench them safely!

STEP 2: WINDING STEMS! (TETSU)

Tetsu hard at work turning winding stems!

STEP 3: CUSTOM TOOLS! (FULLSKILL DAVID)

David realized he needed a support for jeweling purposes that was not commercially available and then made his own!

STEP 4: BALANCE STAFF II! (FRANCESCO)

Francesco in the process of calculating the values the new balance staff need to have, and also comparing the old balance staff size!Francesco working on his second balance staff!

STEP 5: HAND SETTING! (TECHNICIANS)

Technicians learning handsetting!

STEP 6: CUSTOMIZATION! (FRANCESCO)

Francesco made these micrometer jaws for one of his micrometers as the original were too thick!

STEP 7: TOBOGGAN! (EVERYONE)

It was really exciting and fun to ride the Toboggan and ending with a nice picknick!

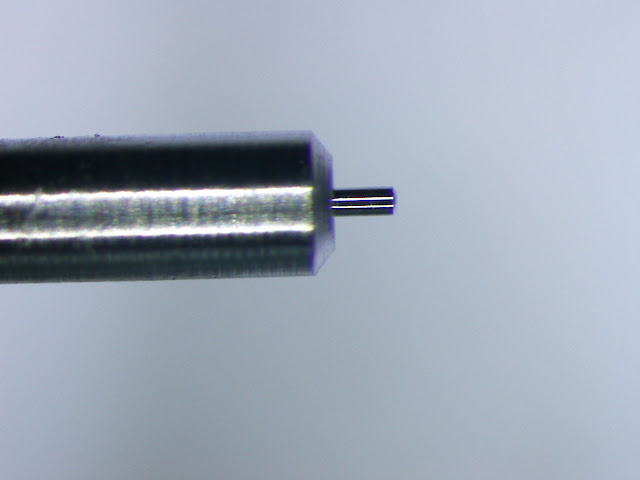

STEP 8: PIVOT GAUGE! (ÅSMUND)

Asmund finished his first nice pivot at 0.20 mm diameter! (pictures taken with different lighting conditions).

HENRIK's WORDS:

It got really busy in all the workshops this week! The technicians continued repairing watches to practice for their final exam next week! Dean and Tetsu practiced for the first time hardening and tempering of their winding stems. David and Renato had their gear train exam and completed almost all the exercises of that course . Robert continued with his pivot gauges and Asmund finished his first nice pivot gauge at 0.20 mm diameter! Francesco continued with a second balance staff. in the middle of the week it was nice to have a student outing as the temperature and weather was really ideal! it was incredibly exciting especially for the adrenalin addicts of the teams :) we ended the week in Mr. Simonins watch/tool bookstore; https://www.booksimonin.ch/ very cool and very busy week!! Have a great weekend everyone!

.jpeg)

No comments:

Post a Comment