WEEK 176

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

Happy Friday!

The technicians have been hard at work preparing for our upcoming final exams. We have continued working on our watch repairs and had a great discussion about after-sales service procedures. During one of our lessons, we were able to remove and repair the case back of a watch that I have had many failed attempts at opening. I’m very excited to finally be able to overhaul this movement.

To end the week, we have started our 16 hour trial exam to give us a look at what to expect in the final exams. While it can be a bit frustrating at times, we are enjoying the process of finding and solving problems in our movements.

Have a great week everyone.

- Lani

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (15~19 August) Dean & Tetsu continued gaining their hand turning experience with the 8 mm lathe. This time, they did slot cutting on blued steel and thread cutting on silver steel.

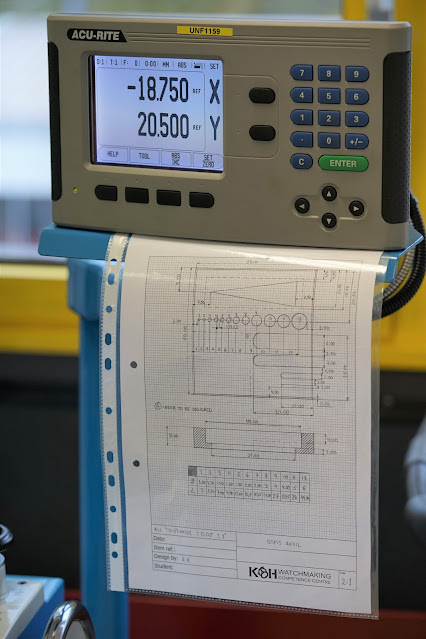

For slot cutting, there were 5 pieces in 5 different sizes, using self-made hard metal (tungsten carbide) gravers to achieve this. The tolerance was down to +/- 0.01 mm instead of usual +/- 0.05 mm, so it required quite a bit of concentration.

Thread cutting, the other task for the week, was done on silver steel wire, which would be the material for our winding stem practice and exam. We used 1.2 mm dies and cut the thread very carefully; another nerve wrenching test.

Apart from the heat treatment lesson coming up shortly, we were ready to make winding stems. Our practice session has already begun.

We wish you all a nice weekend!

Dean & Tetsu

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Hello everyone, this week I made my first balance staff! I took all the measurements from the movement by using an horizontal micrometer and a set of pivot gauges.After that I turned the steps with the Schaublin 102 equipped with the microscope. Once all the diameters and lengths were done I used the Horia lathe to turn the pivots between centers. Finally I burnished both the pivots and the domes as you can see in the photos.

Yesterday I started a new restoration project on an English lever pocket watch. The balance staff pivot was broken and the balance jewel was broken too. So I searched the correct jewel among the billions that Henrik has in his sets and I found it pretty quickly! After pressing it in the setting I assembled it back in the mainplate . On Monday I’m looking forward to start taking all the measurements from the movement and then make it!

Have a great weekend,

Francesco.

STEP 1: OLD TOOLS! (ROBERT)

Robert took the opportunity in between making pivot gauges to work on his brass anvil, specifically to drill and bore the holes.

STEP 2: TURNING! (FRANCESCO)

Francesco turning the body of his balance staff, he later turned the pivots and conical section for the double roller between fixed centres.

STEP 3: BALANCE STAFF PIVOT! (FRANCESCO)

After burnishing the balance staff pivot!

STEP 4: JEWEL! (FRANCESCO)

For the second balance staff that Francesco will make (for the English pocket watch mentioned in previous weeks blog post) he also found that the jewel where the pivot was broken in was not good, but he found a new antique jewel with similar color for it, in the picture it's already inserted in its setting, the right hand one is the broken one, now he is able to take down the dimensions for the new balances staff!

STEP 5: CASES! (TECHNICIAN)

The technicians continued with repairs and studied also the case how to open them with different tools and how to close them, as well as water resistance checking, adjusting winding stems to length and truing crowns to run smooth when winding the movement and setting the time!

STEP 6: BOOKS! (ROBERT)

Robert brought this interesting book about Zenith El Primero watches, seems to be a very good book for anyone collecting Zenith El Primero watches!

HENRIK's WORDS:

We got plenty of rain this week, might as well be good as it has been dry for long time! The technicians got introduced to after sales service procedures and the case of the watch, including how to change and adapt new winding stems for the crown, they also practiced for the final exam. Dean and Tetsu continued practicing for the winding stem cutting slots ending the weak with making their first brass prototype winding stem to get used to the dimensions and locations of the various dimensions. David and Renato had their first gear train trial exam and will most likely have their real one next week. Robert was busy with pivot gauge making and also working on his brass anvil, Asmund continued with pivot gauges and Francesco with balance staff making as well as replacing a broken antique jewel that was necessary before he can take the dimensions for the balance staff he will make for it. very creative and busy week!! Have a great weekend everyone!

No comments:

Post a Comment