WEEK 188

Team A

This week, we practiced more filing and we learned how to use the drill press to make practice pieces for our balance bridge holder, the plate for our pressfit exercise and how to tap the holes to make screw threads.

We also had an introduction and demonstration of how to use the Pantograph for engraving and also an explanation of how to use it to make watch parts.

-Miguel

Team B

Team D

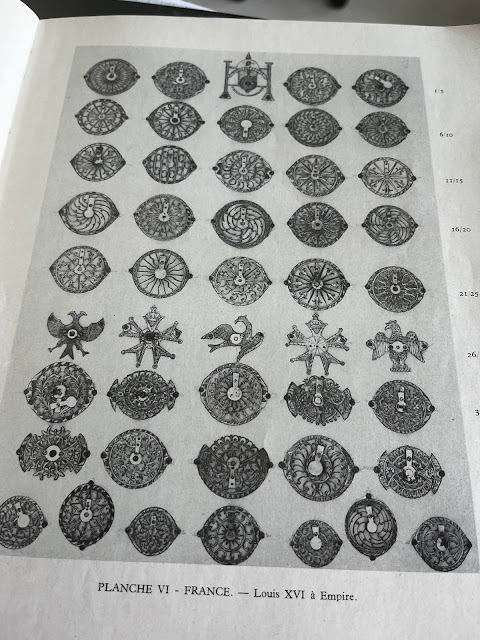

Most of us went to the international watchmaking museum in La Chaux-de-Fonds to get some watches, watchmaking tools and books!

HENRIK's WORDS:

We had several very sunny days this week, really nice!! Most of us went to the Musée international d'horlogerie as each year they have a flee market there, Everyone got introduced to the pantograph machine which is capable of engraving but also to mill out watch parts with! Xin continued with winding and setting mechanisms incablocs! Miguel, David, and Daniel got introduced and practiced also drilling and tapping! Renanto and David finished the escapement course and worked on their own watches! Tetsu and Dean continued with pivot gauges! Francesco, Asmund and Robert learn about jewelled bearings and how to adjust endshakes! It was a very fine week! Have a great weekend everyone!

No comments:

Post a Comment