WEEK 152

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

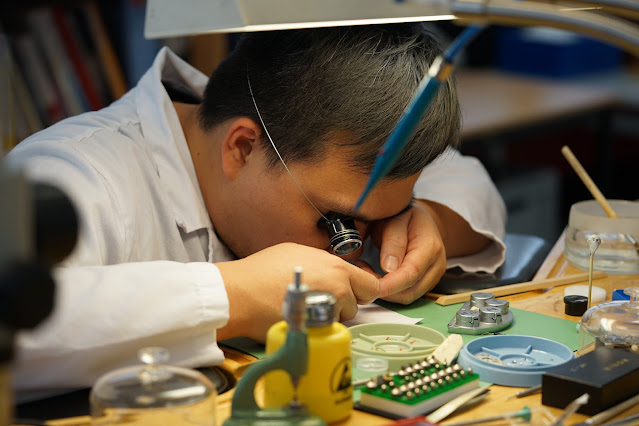

All of the technicians were really serious this week. We had the real exam this week, so everyone was studying hard to ensure that everything was as perfect as possible. However, following the exam, everyone was pleased with the outcome, and the weeks of effort were well worth it. After the exam, we also learned how to apply the proper amount of oil to the wheel pivots of all seven calibers. It takes a lot of knowledge and practice to get things perfect!

Kate Raksina

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (28 Feb.-4 Mar.) We (Tetsu and Dean) continued working on the mandatory tools, which are either compulsory or compulsory & graded. Both of us focused on the steel angular rule and brass wheel truing guide, which have a 45 and 60 degree angles, proving to be challenging to keep within the +/- 0.08 mm and +/- 45 minutes.

Dean has a side project working on a watch with a 6497 movement. The watch’s movement has beautifully finished bridges and a swan neck regulator; however, the balance wheel is a standard grade gilt nickel type. In order to upgrade the movement, Dean sourced a glucydur screw balance and plans to install it in the near future.

Have a great weekend everyone.

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Robert: This week was all about making some winding stem practice parts from brass. I needed to use the Schaublin 70 lathe to make them, then filed one part square using a pin vice clamped in my bench vice, and used the Horia 8mm lathe to hold the next part for square filing.

A slow process of filing makes the squares: there are dimensions to be met, and the size of the parts makes the possibility of them flexing under a file a reality. Nothing happened quickly with this task.

Åsmund: See above!

Hello everyone, this week I’ve done some interesting projects.I did some winding stem polishing, I’ve only finished the big cylinder with the “Black polishing” technique. Then I made a bushing for the ETA 7001 caliber. I used the jig- borer to spot the center of the screw hole and then I used the Schaublin 70 to make the hole and the thread. Then I removed the burrs with the degussit stone and I did the plating of the bushing.

At the end of the week I started a side project for a client. Finally I got the dice that I can use to make a short pitch thread on the piece. At the moment I am starting with the brass prototype, next I will do the steel piece if everything goes well.

See you next weekend,

Francesco.

STEP 1: BUSY! (TECHNICIANS)

Technicians working hard to complete the barrel and gear train course!

STEP 2: HAND FILING! (ROBERT)

Robert started to hand file square bars in brass, 3 more to go!

STEP 3: OVERHAULING! (ÅSMUND)

Asmund decided to clean, inspect, adjust and lube his lathe!

STEP 4: BOOKS (RENATO)

Renato treated us with another really nice book!

STEP 5: FINE DIE! (FRANCESCO)

Francesco received his special die for the case tube and is now ready to make his special tube according to his plan!

STEP 6: WOOD STAND! (ÅSMUND)

Asmund made a stand in wood for his file collection!

STEP 7: UPGRADES! (DEAN)

Dean just received a nice Glucydur screw balance that he will later put in his ETA movement watch!

HENRIK's WORDS:

This week was as last week extremely busy, The technicians finished their exams and learn the lubrication of the gear train. Renato already finished all the mandatory pivot gauges, and will most probably begin trial exams next week. We finally received the fine pitch die that Francesco needed for his special case tube project. We also received Mohmad all the way from India for the taster course/bench test which was nice to see! A very balanced, intensive and sunny week! Have a great weekend everyone!

No comments:

Post a Comment