WEEK 148

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

This week flew by! The technicians were busy learning and practicing oiling for setting/winding mechanisms as well as barrel service. There is so much to learn and we have been having fun trying to figure out all sorts of different movements.

- Lani

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

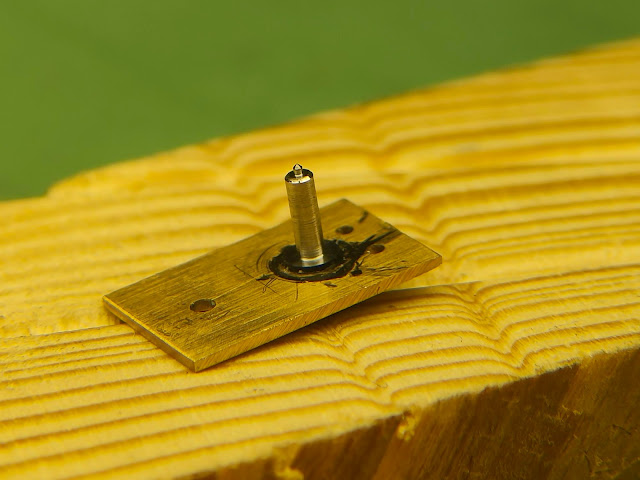

This week, (31 Jan.-4 Feb.) we spent a significant amount of time on the Schaublin 70 lathe turning brass parts for our tools. Of note, we worked on marking parts for the balance bridge support and the rectangular press fit plate. The “mast” for the balance bridge support is only 43 mm long, however; within that space is contained a 25 mm cone of which the diameter must fit within a maximum of 2.5 mm at the proximal end, and 0.5 mm at the distal end. There’s also a 15 mm long cylindrical piece in the middle. Last, but not least, is a 3 mm long size M4 threaded piece for fastening to the base plate. Did I mention that the pass/fail tolerances for this piece are to be within +/- 0.05 mm in addition to a maximum of 1 degree of angle applying to the base plate sides? No pressure!

As we’ve now completed the fourth week of our Fullskill program, we’re really settling in to the class environment and and familiarity with the tools & equipment. Already, we’ve noticed that although we’re only at the start, we’re much more comfortable operating these tools than at the start of January.

Have a great weekend everyone!

Tetsu and Dean

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Continued working on the pivot gauges. Turned a 0.15mm pivot. Works pretty good between centers. Also worked with the Jacot tool the first time for pivot burnishing. Interesting process and pretty safe after some trial. With thin pivots, pressure must be kept low. Impressive what can be done with the right tools!

-Renato

STEP 1: WATCHES! (RENATO)

The Longines Ultra Quartz movement out of its case, very serious electromechanical engineering going on here!

STEP 2: ENERGY ACCUMULATOR! (TECHNICIANS)

STEP 3: PIVOTS! (RENATO)

His own pivot gauge before turning it down!He got it down to 0.15 in the end, not bad for the first pivot he ever turned between centres in hardened and tempered steel!

The first ever pinion pivot Renato burnished, looking pretty nice!!

STEP 4: PHOTOGRAPHY! (RENATO)

Renato lend the school a special tube that can be mounted in the back of the lens and now we can take amazing looking pictures of watches! Great idea!

HENRIK's WORDS:

We got some rain that froze on impact and caused a thick glace as a coating on cars this week, must have been around 0°C for that to happen. Renato was practicing burnishing this week, he used an old test pocket watch wheel to practice on with 0.20 mm pivots. The technicians learned to deal with barrels and mainsprings this week which was very interesting! David continued with winding stems but this time to make them for some of his antique and vintage watches. It was a very fast week but also very enjoyable. have a great weekend everyone!

No comments:

Post a Comment