WEEK 147

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

Finishing the week off strong with some assembly and disassembly practice on movements 6497/8 and 7001! This week we learned how to properly care for and maintain tools, as well as the cleaning and oiling process for Incablocs and setting mechanisms on movements. It has been a lot of hard work, but we have all been excited to start focusing on the components of a watch. Can’t wait to see what next week has in store for us!

-Leilani

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (24-28 January) Dean & Tetsu had an opportunity to learn how to operate the Agathon grinding machine, which we mainly use to sharpen our gravers for the lathe, such as the Schaublin 70. Henrik demonstrated 10 different adjustment possibilities to play with, but once the set up is done, the actual work itself would be completed within a minute or two; another example illustrating the importance of preparation!Dean had a taste of the drilling machine for his plate while Tetsu tried to work on a lathe to gain more experience and improve their skills with help from Henrik and Michael.The rest of the time we continued sawing and filing by hand for whole days, which may be a kind of torture for some but we enjoy doing it.Nowadays, CNC machines can do almost anything, and those tasks we are performing would take a fraction of a second, but we are here to learn how to make everything without relying on computers.Our hands will be involved in every single step of watch and tool making and we hope that one day, we will properly understand the meaning of our assignments in the micro mechanics portion of the Fullskill program.We wish you all a great weekend!

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

I started working on the pivot gauges. Made some nice brass driver plates on the jig borer and prepared the blued steel double cone base pieces. Started turning with carbide as well as high speed steel gravers. Both actually work fine. Also made some shims to reduce play in the 8mm T rest. Then we checked out an interesting Longines quartz movement. I tried using a polarizing filter on the mobile for watch photography. Works pretty nicely!

-Renato

Hello everyone,

This week has been going very fast, ive mostly been finishing up the jaws for the micrometer. Spent some time experimenting with different setup for the tempering to get a perfect blue colour. Both hardening and tempering went well, so I’ve spent the last two days doing the last finishes and black polishing. Will assemble it this weekend and take some more pictures of it assembled all together for next week blog post.

Meanwhile you can enjoy the picture of the jaws and screws 😊

Have a great weekend

Åsmund

STEP 1: MACHINING! (ÅSMUND)

Asmund finished his jaws and screws for his micrometer, stunning looking!!

Asmund finishing one of the screws for his micrometre jaws!

Asmund finishing one of the screws for his micrometre jaws!

STEP 2: MACHINING! (ROBERT)

STEP 3: FULL HOUSE! (TECHNICIAN)

STEP 4: WATCHES! (RENATO)

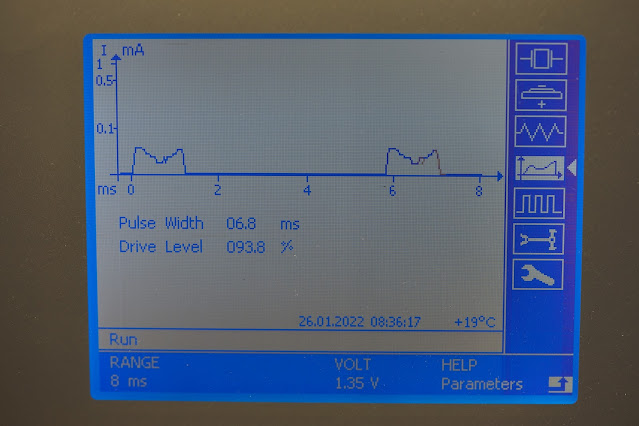

Yes its alive!!

With a new battery the movement did not run, but after cleaning the battery terminals it was running again!

With a new battery the movement did not run, but after cleaning the battery terminals it was running again!

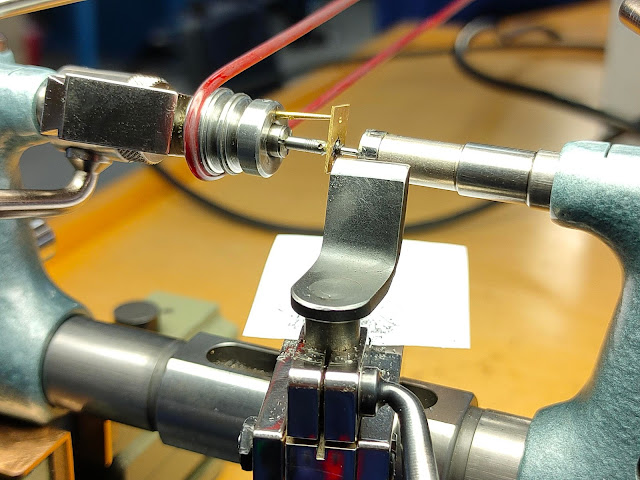

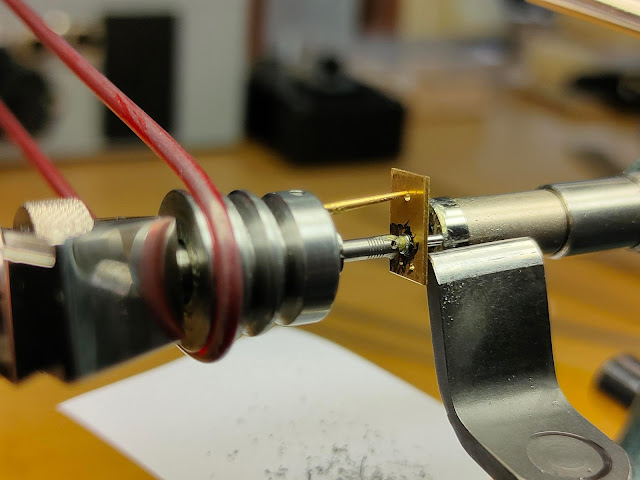

He ordered a specially modified battery that would produce 1.35 volt instead of 1.55 volt that we most commonly use today in quartz watches.

He got very curious as to how a 1.55 volt battery can be converted down to 1.35 volt so he took it apart accidentally as he was modifying the plastic ring to fit inside the battery opening!

Unfortunately due to the unusual frequency we cant trust the rate readout. Massive consumption is probably the right reading though, 11.7µA compared to modern quartz that can be around 0.70-1.30µA, technology has come a long way!!

STEP 6: HAND FILIING! (TETSU)

Tetsu checking the flatness and straightness of one of his very narrow brass filing exercises, it is here standing up on the short side, its difficult to see it as we are looking at the thin side!

STEP 7: CARRIERS! (RENATO)

STEP 8: TURNING BETWEEN CENTRES! (RENATO)

Renato also tried out to hand turn hardened and tempered steel between two dead centres in the Horia lathe!

STEP 9: PHOTOGRAPHY! (RENATO)

Renato wanted to find a way to have less glare on the watch crystal on his photos, the above photo he took with his phone.

He found a cheap solution by mounting a special lens that reduces glares over his phone lenses! Much better!

He found a cheap solution by mounting a special lens that reduces glares over his phone lenses! Much better!

STEP 10: WATCHES! (RENATO)

Renato brought an interesting watch for show!

STEP 11: GRINDING GRAVERS! (TETSU & DEAN)

STEP 12: STEAMING! (EVERYONE)

The students were working so hard this weak that the surroundings of the school warmed up so much that most of the snow melted and even the hill started to steam! ;)

HENRIK's WORDS:

Very fast week! And very busy! It was also really enjoyable! have a great weekend everyone!

No comments:

Post a Comment