WEEK 112

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This week a lot happened from movement work, consisting of various different checks and additionally demonstrations for other smaller modules. These demonstrations consisted of the Automatic module, encasing work, repairing the winding stem and correcting a tilted crown. These demonstrations where spread out from the middle to the end of the week. Which in addition to the main work made the week very dense.

There were lots of issues with this watch before Yuriy got it to run again, Its alive and well again and he did some really nice black polishing on some parts and polishing and bluing on the screws that are shifting to purple which looks really cool with the blue jewels!

The plan!

HENRIK's

WORDS:

Finally, we got some sun! Things are

looking brighter now and even our friends came for visit 😊 Very busy week for

everyone! Yuriy and Willy will soon leave us and it will be a bit sad, however,

we will very soon receive new students! The perfect circle continues! We

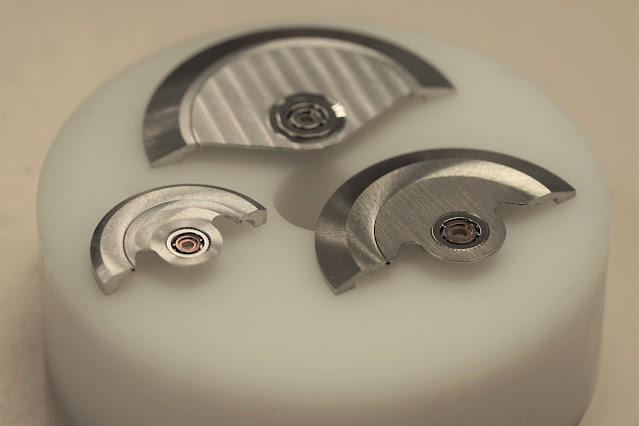

covered some last aspects of the technician course such as the automatic watch,

ball bearing replacement, hand setting, water resistance issues how to deal

with different type of cases etc. Yuriy finished one of his side projects, a beautiful

pocket watch with a Zodiac movement with blue jewels! Absolutely stunning

looking movement! On this project he learned black polishing as well as bluing

screws, making bushings to replace the worn ones among many other techniques to

make it run with good amplitude and timing ones again, and he even learn how to

gold plate, unfortunately the hands he wanted to gold plate did not fit in the

end so he had to use the old ones, but at least he learned the process! David

and Renato continued machining tools and learn how to extract a broken screw from

a tool holder which is always an interesting process!

Willy handed over a unique special commemorative

plaque as a token of appreciation of the education he received, what an honourable

thing to do! Thank you so much Willy! we will certainly never forget you!

We probably covered more things this week that

I already forgot about as the week was so fast! It was an awesome week overall!

Have a great weekend everyone!

Watch Battery Replacement is a complicated task, and you must hire an experienced reconditioned dealer for this.

ReplyDeleteIf you want to buy or sell rolex watches at the best price, always choose local and trusted watch dealers because they never disappoint their clients regarding their job.

ReplyDelete