WEEK 167

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

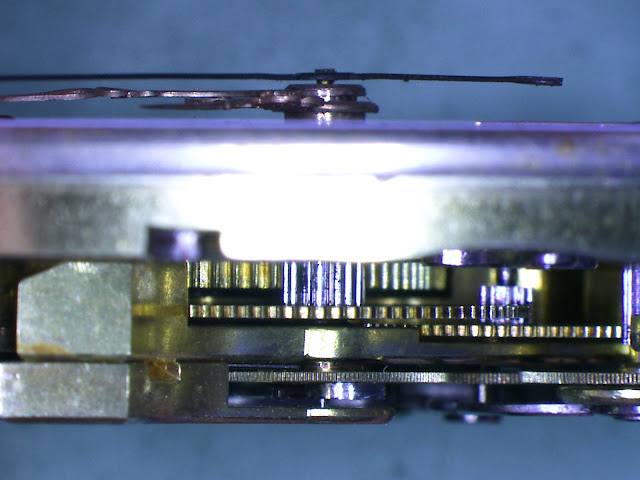

This week the technicians started the second trial hairspring exam. We are focusing on riveting, flatness, centering of hairspring and poising balance. The exam is very challenging, as all exams are. It is one thing to finish each task on your own, but to finish on time is a part of the exam, too. It's great that everything has significantly improved for our second trial exam.Kate Raksina

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

Tetsu and Dean

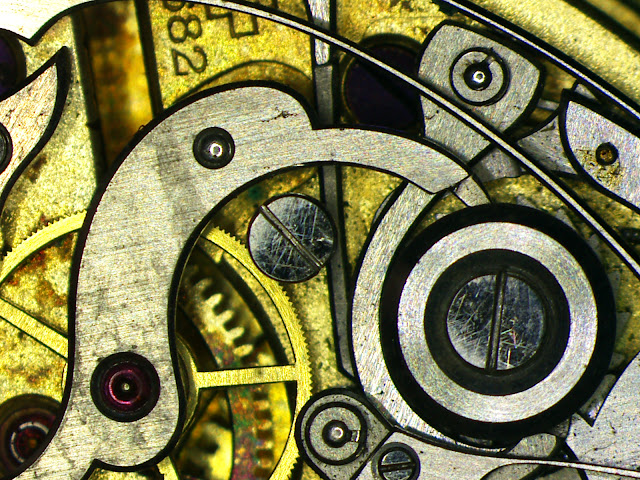

More than five months having passed since Tetsu and Dean started the Fullskil program; where did the time go?!This week, Tetsu finished his barrel closing tool, with which he finally had some experience with the Schaublin 102. It means that both have finished their graded and non-graded mandatory tools. Tetsu and Dean are now looking forward to using their newly-aquired micro mechanical skills in the next part of the Fullskill program.

Dean worked on doing some light restoration work to his Rolex Oysterquartz Ref. 17000 (see separate blog post below) and performing repairs to some tools he acquired in preparation for later coursework in the program.Have a great weekend everyone!

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

This week we visited the EPHJ trade show. We saw many interesting companies. It was nice to see how technology and digitization is shaping the future of the watchmaking industry. Asmund worked on winding stems, Francesco on pivot gauges and cleaning his new collection of movement holders. Robert worked on winding stems. I continued to work on cleaning and oiling the keyless works.

-David

STEP 1: VISIT! (EVERYONE)

STEP 2: VISIT #2! (EVERYONE)

STEP 3: VISIT #3! (EVERYONE)

STEP 4: EPHJ! (EVERYONE)

STEP 5: BALANCE AND HAIRSPRING! (TECHNICIANS)

STEP 6: ROLEX OYSTER QUARTZ! (DEAN)

Dean continued restoration work on his Rolex Oysterquartz watch by disassembling the case & bracelet parts. A trip to the ultrasonic cleaner yielded some great results. After installing a new crystal, tube, and gaskets, it was ready for many more years of use.

STEP 7: WATCHES! (DAVID)

STEP 9: WINDING STEM! (ÅSMUND)

HENRIK's WORDS:

Summer arrived! The temperature got as high as 28°C! The visit to Philippe Narbel was great!! He was really kind and spend a good amount of time with us showing his workshop and giving valuable tips and tricks regarding high end finishing! We also went to EPHJ in Geneva to network and check out some tools and machines! It was a very busy but fantastic week! have a great weekend everyone!

.jpeg)

okok.jpeg)

.jpeg)