WEEK 162

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

The technicians are hard at work on their balances, with hairsprings yet to come. We have been removing the rollers from the balance staffs with two entirely different techniques, after which we remove the balance staffs by first grinding part of the staff off from the underside of the balance wheel and then popping the remaining staff out using the staking set. Obviously, the balance staffs will be useless after this procedure as our primary goal is to retain and maintain the balance in undamaged condition.

Next, we place the new staff in the balance and rivet the staff to the wheel. The process of riveting, when it comes to watchmaking, is a process by which the metal of the balance staff is moved and shaped so as to capture the balance wheel snugly, thusly ensuring that the balance and staff work together as one unit. It’s an exacting process that requires numerous specialized tools.

We then press fit the old (or new) roller onto the bottom part of the balance staff and position it in a precise location with respect to the spokes of the balance wheel. Then we check the tightness of both the staff to the balance and the roller to the balance staff. We inspect the all important pivots to ensure maximum performance of the watch and then we actually true the balance wheels at precise locations to attain perfect flatness.

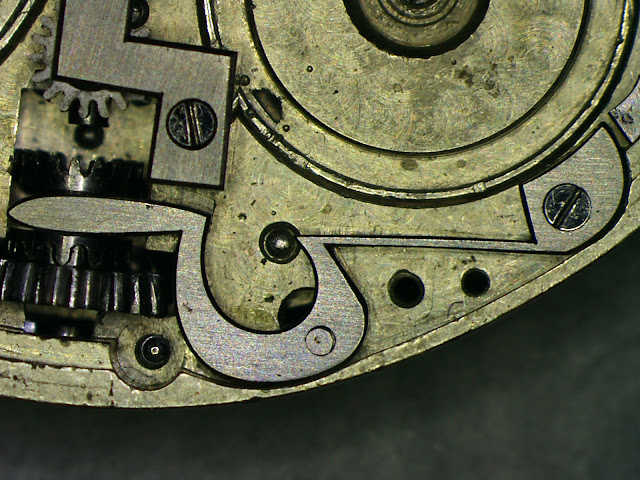

The last task is to statically poise the balance wheels. This is done using another specialized tool and some judicious reduction of the balance at specific points in order to achieve a perfectly balanced wheel. Even something as small as a very fine piece of lint or the weight from a small dot of a marking pen on the balance will throw the entire balance significantly out of alignment. Exacting work, indeed.

We are gearing up for hairspring work in the coming weeks and will then see our hard work pay off when we begin to check the timing of our movements. Spring is here but the technicians will be staying inside-to continue the tradition of fine watchmaking. Corny, but true!

David

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (9-13 May) Tetsu and Dean continued work on their tools with four months into the Fullskill program solidly behind them.

Henrik graded (and passed) Tetsu’s polishing tripod, which he is happy to have completed. Tetsu worked on his pointed nose head vice for the balance of the week, using the milling machine for cutting the basic shape; and the jig borer for drilling the holes. The head vice comprises of two parts held together with fasteners, so precision is especially important for ensuring the holes line up.

Henrik graded (and passed) Dean’s pointed nose head vice, which was a nice small win to celebrate as he continued working on his brass anvil. Dean worked on a significant amount of practice pieces with composing a checklist to insure each action on the milling machine is done properly.

Despite it being Friday the 13th, Tetsu and Dean regard themselves as lucky to have accomplished as much as they did this week.

Have a great weekend everyone!

Tetsu and Dean

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Robert- This week was a continuation of the "Winding Stem" saga. Trying a different method of containing a winding stem for heat-treatment to eliminate (or greatly reduce) the possibility of them being curved/bent as a result of the high heat and rapid cooling used in this process.

I also cut a large supply of blanks to use for winding stem testing next week. Then we'll see if all the research and development can all be combined for positive results.

Francesco- Started making precision pivot gauges this week. (How do you measure s-m-a-l-l holes? With gauges that you make in a selection of those s-m-a-l-l diameters and use for Go/No-Go measuring.)

Åsmund- This was a week as noted above, a continuation of the "Winding Stem" saga.

(All as submitted by Robert.)

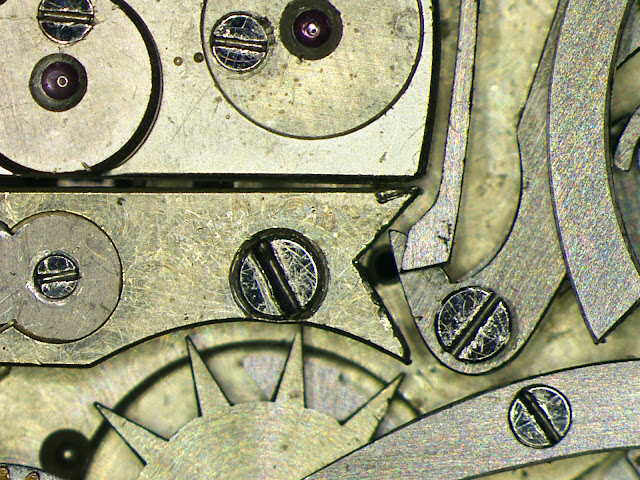

STEP 1: THE MTM DEVICE! (TECHNICIANS & RENATO)

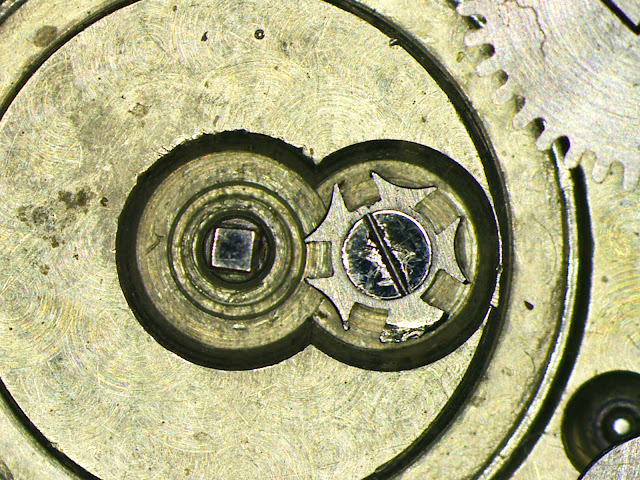

The technicians learn how to refresh balance staff pivots that had minor imperfections with this tool from Horia that they call the MTM device, it's a type of pivot lathe or tool for burnishing pivots, like a Jacot tool, great easy to use tool for restoration and also small production!

A in the process of refreshing pivots and poising!

STEP 2: POISING! (TECHNICIANS)

Leilani and the technicians poising the balance!

STEP 3: HANDLE! (RENATO)

Renato made this handy handle to hold gravers when re-sharpening them but also when using them!

STEP 4: MILLING! (DEAN)

Dean was busy on the F1 working on milling slots for his brass anvil!

STEP 5: HOUR WHEEL! (RENATO)

Renato learning something new, how to make an hour wheel, here he is setting up the Schaublin 70 lathe with the milling head with the cutter installed!

STEP 6: TOOLS AND EXERCISES! (RENATO)

Renato finished his press fit exercise!

And also his brass anvil!

STEP 7: TOOLS! (EVERYONE)

It was nice to have Sabri swing by with some useful tools for us!

STEP 8: MOVEMENTS! (RENATO)

Another beast of a movement from Renato!

HENRIK's

WORDS:

This

week it got very hot in Le Locle, at its peak, it got as high as 23 degrees

Celsius, lots of sunshine and everything turning green and yellow! We had Sabri from Neuchâtel swing by the school with some second hand watchmaking tools, he also has movements and spare parts which was nice to know! The

technicians continued trueing the balances in the flat and also statically

poise them, connected to this was the conditions of the balance staff pivots, especially

for vintage balances, for which they found that not all pivots are in good

condition, some have flat spots, scratches small bends etc. they detected this

visually in the microscope but also during the static poising procedure as the

balance would not roll smoothly on the static poising tool, If left, this will

certainly influence the timekeeping in a bad way, so for the pivots with minor

defects they learn a way to refresh them without modifying the size much. Francesco

and David continued making pivot gauges, and Robert continued making winding

stems. Renato has finished all his tools and started to make wheels. Dean and Tetsu continued

machining tools. It was a very enjoyable week! have a great weekend

everyone!

No comments:

Post a Comment