WEEK 159-160

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

I hope everyone enjoyed their Easter holiday.

The technicians came back from break feeling refreshed and ready to work! David had a great time visiting Paris while Kate, A, and I enjoyed the long weekend exploring Zurich.

We have all passed our Escapement exams and spent the short week finishing up our total lock and pallet fork cleanliness homework. Now, we are all starting to work on various movements for repair points to qualify for our final exam.

To end the week, the technicians had a lecture about escapement theory and discussed some interesting escapements that have been developed over the years. It’s incredible to think that over 600 iterations have been made!

Have a great weekend

- Leilani

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week (20-22 April 2022) was a short one on the heels of the Easter weekend, so Tetsu and Dean caught up with working on their tools from the previous week. Tetsu worked on his brass anvil, which he gave to Henrik for a progress check, and the base for his poising plate. The brass anvil has a significant number of milling and drilling operations, so adherence to tolerances are especially important here. The base of the poising plate has an angled slot, so this tool, although not as complicated as the brass anvil, still requires attention to detail to maintain symmetry and proportions. On this tool, Tetsu is also experimenting with surface finishing.Dean worked exclusively on his pointed head nose vice, which is another tool involving angles which need to stay within the scope of the predetermined dimensions. Once the basic brass pieces are cut, they will be glued together, where they will remain as a single until until the cutting, drilling, and threading operations are completed.Suffice to say that Tetsu and Dean have their work cut out for them for next week!Have a great weekend everyone!Tetsu and Dean

This week, (25-29 April) Tetsu and Dean continued working on their tools. Tetsu finally finished his brass anvil, which was graded & passed, in addition to completing work on his poising plate. He is now working on his polishing tripod. In so doing, Tetsu spent the majority of Friday at the jig borer to create four holes using drills and a bore cutter. He also used the three-jaw chuck to reduce the diameter of the pin vice to be used in the polishing tripod. Dean has almost completed his poising plate and is preparing to make some of the angled cuts on his pointed head nose vice. In order to make this happen, Dean will need to use the milling machine the rotating table with angle indicator to obtain the perfect shape for the nose of the vice.Have a great weekend everyone!Tetsu and Dean

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Designed the balance staff for my split second pocket watch movement before the Easter holidays. Taking the measurements was interesting, as there is always some uncertainty in how accurately one can measure. After double and triple checking them, I then started making the staff on the big lathe with the microscope and finished on the 8mm lathe and Jacot tool. Very many steps are needed and one can optimize the process individually. Extremely interesting task, probably one of the hardest part to make in restauration. Staff is done now and it fit pretty well. Roller and balance will be fitted later but end and side shake are good. Pretty cool! -Renato

Another winding stem week, perfecting making winding stems to various dimensions as given by Henrik. Turning the stems with hand-held gravers is the first part of these trials, the second part is doing the hardening, tempering, and any straightening necessary. A dial indicator is very helpful for straightening, showing precisely where, and the amount of the error that is to be eliminated. Then using various limiting devices to prevent the winding stem from exceeding it's elastic limits (breaking) during straightening. Fortunately, it seems that a straight stem that starts the heat treatment process will stay straight. But knowing various methods to solve problems are always good arrows to have in one's quiver. -Robert

STEP 2: EASTER! (LEILANI)

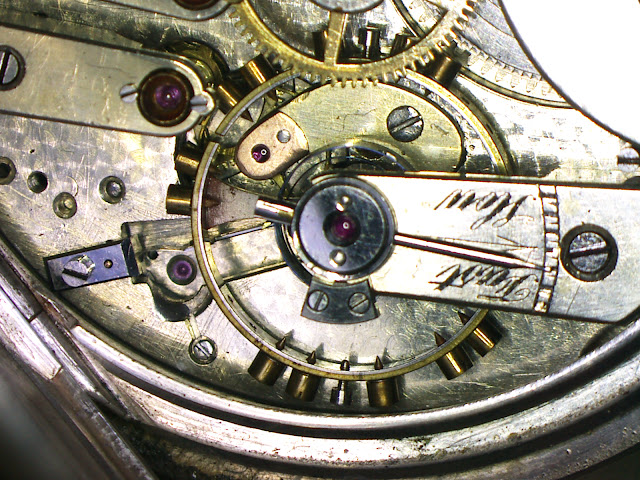

STEP 3: VINTAGE! (TECHNICIANS)

STEP 4: TRIPOD! (RENATO)

STEP 5: TURNING! (FRANCESCO)

Francesco was working on multiple things, here he is going to make a perspex support for one of his micrometers!

STEP 6: BOOKS! (DAVID, FULLSKILL)

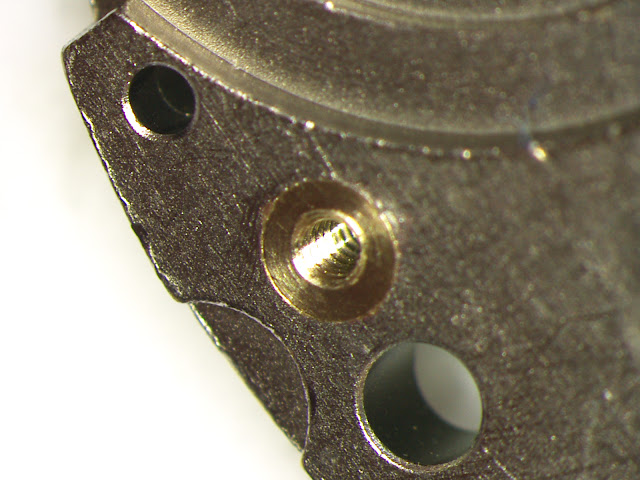

STEP 7: THREADED BUSHING! (DAVID, TECHNICIAN)

David in the technician course made a threaded bushing for one that had a stripped thread in the mainplate!

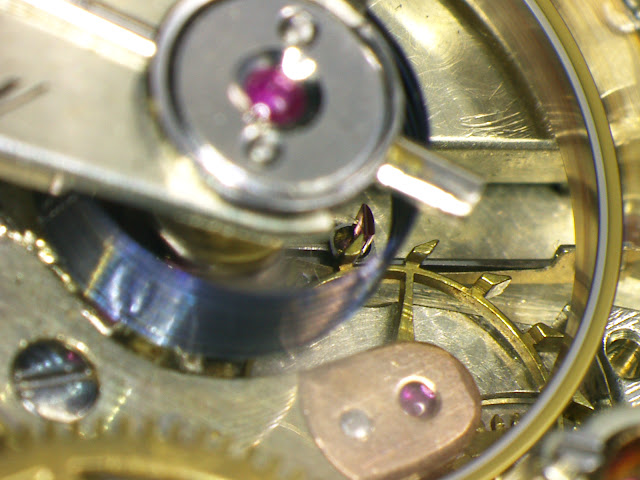

STEP 8: SPRING DETENT! (RENATO)

HENRIK's WORDS:

Easter was great this year, we got really perfect weather! As last week was so short, we decided to do the blogpost this week instead. The technicians completed the escapement course and started a new exciting subject; the balance and balance spring course including the timing. We had Simon from England here taking the taster course/bench test which was nice. Renato finished his balance staff for his pocket watch Asmund and Robert practiced making winding stems and Francesco working on tools and also got introduced to turn between centres, It was very busy but enjoyable! have a great weekend everyone!

No comments:

Post a Comment