WEEK 127

Michael

Origin : Malaysia

Watchmaking class: Technician & Fullskill

Current mood: I did some repairs and at the same time doing a private project from Yuriy regarding a small pinion stem that turns an inner bezel for zodiac diver watches. It was totally a new thing because the pinion that the watch has does not follow any watchmaking standard pinion shape and I have to shape the cutter and learned a lot regarding relieved cutters. Looking forward to next week for more micro mechanics.

Renato & David

Origin: Zug, Zürich, Switzerland

Watchmaking class: Fullskill

Current mood: Did not initially think it would take that long, but... this one became a finishing week! At least the finish of my winding stem is 99% done :) It's good though, because this time is needed anyway to get experience with finishing tools and all the polishing compounds available. Tried out tetrabore and diamond based polishing pastes in various grades, as well as fine grinding papers. Application was done with brass, steel and different woods. I think I got it figured out to a high degree, but perfect results require a lot of experience. Each piece is individual and needs to be approached in different ways. It was a lot of fun experimenting and finding my own way to reach desired results. Quite happy, considering it's the first stem I ever made! Renato

This week I worked on the 8mm lathe. I was hand turning which was really difficult. The goal was the same as last week to create a conical pivot that matches a certain predetermined radius. Which is the same process when someone is making a balance staff. The curvature of the radius gauge, simulates the curvature of the burnishing tool edge. After a whole week I finally managed to finish the three pieces with; 1.0, 1.5 and 2.0 radiuses. David

Francesco, Åsmund & Robert

Origin: Italy, Norway, USA

Watchmaking class: Fullskill

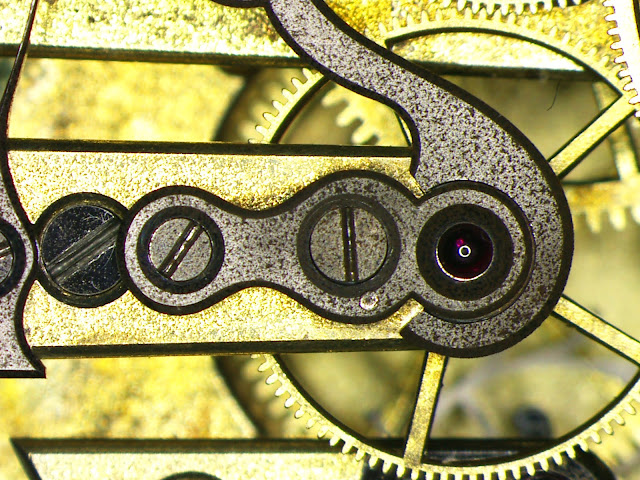

Current mood: This was the last week of heavy filing because I’ve finished most of the tools required for the grading. I’ve just finished the rectangular press fit plate. After filing a rectangle, I’ve made three holes with the drilling machine. After the lesson I started practicing with female cones at the Schaublin 70. It took a little while to find the right technique and how to hold the high speed steel graver in the correct way but at the end I’m happy with the result. Now I’m looking forward to learn the finishing techniques next autumn to finish all the tools.

Have a nice weekend. Francesco

Hello again!

Last week me and Fransesco did the filing exam. Did the exam on Thursday and got the results on Friday and got very satisfied with the results. Made it a nice weekend!

This week I’ve finished the balance bridge holder which were done in the lathe. Took a few tries before i got it to the right measurements.( note to self, always listen to the teacher and not the students 😂) - and started on the steel angular ruler which I’ve been working on for two days. It’s a time consuming task because you are moving back and forth from the bench and the profile projector to check that you are within measurements( +-0.08mm and +- 30 min ) and that the angles are right. I’m using a ball device to hold it and it’s very convenient to use for filing from all kinds of angles.

Until next time

Åsmund

STEP 1: BENCHES! (ALL)

Indeed very solid benches!

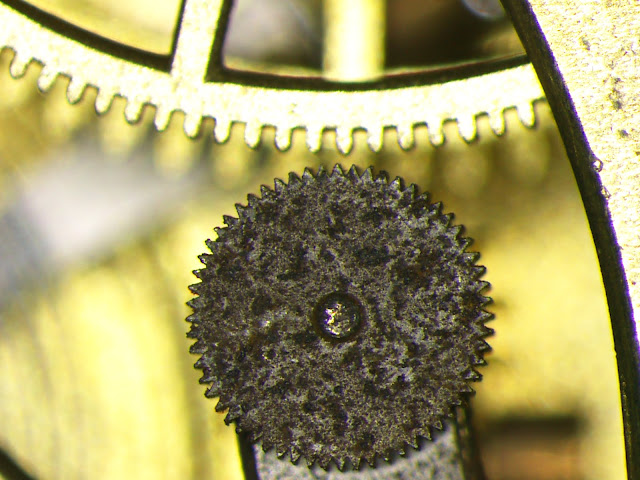

STEP 2: MODIFICATIONS! (MICHAEL)

In between servicing watches with ETA movements in preparation for his final exam, he got a special project to make a pinion and for that we decided to try to modify an existing cutter before ordering one, hopefully it will work out!

STEP 3: FINISHING! (RENATO)

As Renato completed his first ever winding stem last week, he continued this week trying out various technics of finishing the different areas of the winding stem and got some nice results!

Not bad considering its the first winding stem he ever made!

STEP 4: BOOKS! (RENATO)

For any Longines fan or collector this is a must have bible!!

STEP 5: WATCHES! (RENATO)

Another restoration project from Renato! One day this will be a beauty once again!

HENRIK's WORDS:

Thanks to a very nice person affiliated to the school, we got two watchmaking benches of really high quality! they will come in very handy soon and enable us to be even more flexible whenever needed! Thank you so much for thinking about the school!! Everyone got really excited upon the arrival of these benches, very solid heavy ones! Renato practiced a lot of finishing techniques on blue steel scraps and later applied some of those technics on his winding stem, it came out really nice! we mostly worked on similar things as last week so not too much new, hopefully next week we can start with the manual milling machine the Aciera F1 and also some students will most likely go to EPHJ as well. Have a great weekend everyone!

No comments:

Post a Comment