WEEK 118

Alex, Michael

Origin : Taiwan, Malaysia

Watchmaking class: Technician & Fullskill

Current mood: Alex and Michael both did theory lessons this week to cover up all of the theory questions they had. Alex did his Theory and Oral exam on Thursday. Fingers crossed. He did his scratch sheet and broken part preparation today and will be having his final exam next week. Wish him luck and all the best. However, Michael continued with his balance staff making. Had to slightly modify the burnisher because it does not produce a beautiful radial curve on the pivots. Hopefully we can see some hand turned balance staff next week.

Renato & David

Origin: Zug, Zürich, Switzerland

Watchmaking class: Fullskill

Current mood: Made use of the fact that the milling machine was free this week and milled the whole week. Had lots to mill. Milled the 2 halves of my custom poising vise, glued them together and milled the 'pit' where the balance will eventually go. We had a little investigation in finding out why sometimes the zero 'changes' on the machine. Finally we figured it had to do with too fast manoeuvering of the slides when repositioning the end mill. Something applicable to e.g. lathes as well. Good lesson that is not mentioned in any machining book. Also finished milling my custom end pieces of the pointed head nose vise. And finally got some teflon & titanium coated razor blades... not for shaving, but for finishing internal corners on brass pieces. Curious if the high tech coating make any difference :) (Renato)

This week I worked on making a measuring gauge out of steel. I met some difficulties by marking the outline of the shape of tool too light. Also the markings I made were parallel with the graining of the stainless steel, which also increased the difficulty of it being legible. I had to remake the same piece multiple times as overfilled the piece, as I could not see the outline of the markings that I made. The solution I found was to mark the steel opposite the graining, and I went back and remarked it, also adding lines .20 and .40mm away from the real lines for safety. I was successful in filling the piece out, next week I will continue to fine tune the corners. (David)

Francesco, Åsmund & Robert

Origin: Italy, Norway, USA

Watchmaking class: Fullskill

Current mood: N/A

STEP 1: MACHINING! (ÅSMUND, ROBERT & FRANCESCO)

The dividing head!

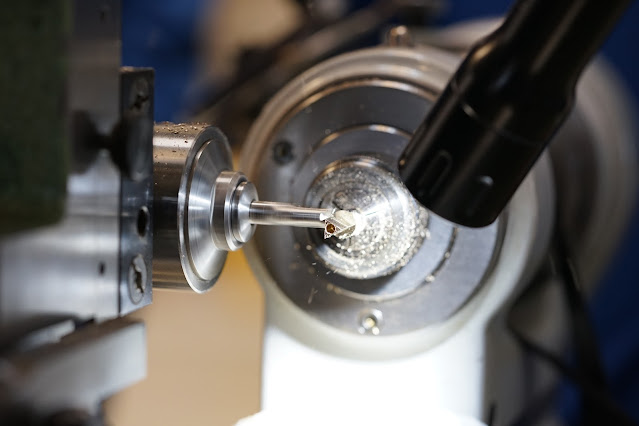

Learning to mill basic shapes in the lathe!

Making a nut!

STEP 2: MILLING! (FRANCESCO)

Francesco setting up the lathe for milling!

STEP 3: TEA TIME! (MICHAEL)

Michael setting up his tea before burnishing balance staff pivots!

STEP 4: BOOKS! (RENATO)

STEP 5: POINTED NOSE VICE! (RENATO)

Renato continued with the next steps of his pointed nose vice, starts to look very interesting!

HENRIK's

WORDS:

So,

this week was another creative one! We covered the dividing head of the Schaublin

70 which provides very precise angular positions of the spindle, this is used

when for example a wheel or pinion needs to be made in restoration as one would need a certain

number (depending on the number of teeth or leaves that needs to be made) of

exactly equally divided positions of the spindle to mill spaces in the material (to be the wheel or pinion) and the left over would be the teeth or leaves, and since we anyway learned how

to use the dividing head, we also learn how to use the milling head of the

lathe. Michael resumed his balance staff making and Alex took his final oral

and theoretical examination and started to prepare for next week’s practical

final examination, wish him good luck! Renato and David continued with machining

some of their tools as well. At the end of the week, we even had some time to see

how a centring microscope can be used with the Schaublin 70 due to Francesco’s

very creative projects suddenly requiring all this knowledge, which is very beneficial

for everyone! Have a great weekend everyone!

No comments:

Post a Comment