WEEK 80

Pierre Aubert

Origin :Toulouse, France.

Age : 24

Watchmaking class: Fullskill

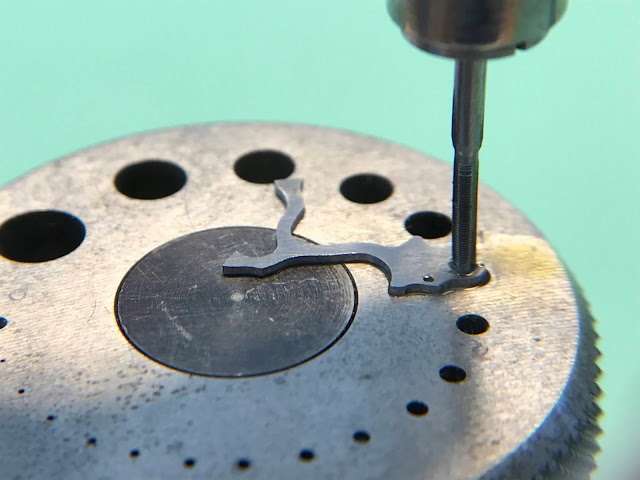

Current mood: I dedicated most of the week to drill the remaining holes for my bridges: escape wheel, crown wheel, ratchet, second gear train bridge screw and a second pin for the balance bridge. For the gear train bridge screw I had to file the bridge equally in order to be able to measure the available space for the screw. I then had to chose an appropriate location for it, it will be asymmetric and give a look that I like :) One side has a screw at the bottom, a pin at top while the other has a screw at the top and the pin at the bottom. It’s getting cold here, have a good weekend everyone!

Name: Markus McDonald.

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This week we had the chronograph course this was nice as it allowed me to focus on personal work specially the pivot gauges.

For the pivot gauges I adopted a production style where for one step at a time I made several pieces.

This started by getting all the pieces together and checking overall quality of the body, next in the Bench lathe I would divide the body into two sections. Then checking the quality and getting the bodies as good as possible. Next degussit Stone and finally the burnishing.

This method worked out very well as I was able to make each step as good as possible reducing chances of error.

In conclusion this went very well and I was able to make a couple of pivot gauges a long with getting 85% of the body done.

Origin : Malaysia

Age : 28

Watchmaking class : 2 years Fullskill Program

Current Mood: This is the individual week for us since there is a chronograph course week going on. Have been doing my pivot gauges coursework for the week and it is getting there slow and steady. The new technician course student is here and I will be starting my technician course with him. Can’t wait to start the new journey.

Alex

Origin : Kaohsiung, Taiwan

Age : 27

Watchmaking : 2Y Fullskill Program

Current mood: Nothing much to say, the week of turning pivot gauges. I am all the down to 0.11 now. Hope nothing breaks, fingers crossed.

STEP 1: VINTAGE CHRONOGRAPH COURSE! (STEFANO & JAMES)

James checking a vintage chronograph.

Stefano checking and adjusting the vintage chronograph movement.

Checking the original hammer position and function.

James drawing the original hammer in the profile projector.

Milling the new hammers in the pantograph

Milled hammers, two for each, Valjoux 22 and Valjoux 23.

Tapping the holes.

Heat treatment between two steel sheets to keep hammer protected and hopefully flat after quenching.

Finishing the hammer.

New hammer in movement.

Checking the function of the new hammer.

STEP 2: BIRTHDAY! (MARKUS)

STEP 3: SCHOOL WATCH! (PIERRE)

Drilling the final screw holes to the bridges.

Modification to the mainplate.

All screws and pins in place for the bridges.

HENRIK's

WORDS:

Very exciting week

indeed! Stefano and James came back for a more advanced subject. This time to

study the vintage chronograph and its restoration and repair in depth, we

covered a lot! Apart from learning the classical chronograph rules and

adjustment points, analyzing the mechanism etc. they both even made two return

to zero hammers each from scratch, one fully adjusted with some finish, and a

spare one for later use for a real restoration project. Also Willy from

Singapore arrived for the technician course, and Markus had his birthday. A

very efficient and smooth week! Also another Henrik’s Minutes short video was

published about screwdrivers by The Naked Watchmaker; https://www.thenakedwatchmaker.com/blog/2020/7/28/henriks-minutes-tweezers-the-watchmakers-first-tool-b2mgd?fbclid=IwAR3VAzr8WaluG4s0eWMXiSMRC4VUmsWvz7uJq5HoHm9jg0b_xKxIjCFeyys Thank you! Have a

great weekend everyone!

No comments:

Post a Comment