WEEK 72

Pierre Aubert, James Punshon, Jayne Zhuo

Origin : Sydney, Australia. Toulouse, France. Singapore.

Age : 38

Watchmaking class: Technician Course

Current mood: James here! First week back after a lovely Swiss summer break. Hardest part of this week was remembering where I put all my rodico!

Finished off our repair module this week, which for my self included a restoration of a 1920's Lemania Chronograph, which i really enjoyed. Strangely enough, this was made here in La Chaux-de-Fonds, but I purchased it in my home country of Australia. It made it around the world and back again!

Preparations have begun for the final exams. The next few weeks will be busy, but I think everyone is excited to show what we have learnt!

Until next time!

Name: Markus McDonald.

Origin: Stockholm, Sweden.

Course: 2 years full skill course.

Current mode: This week: After a long and necessary holiday we returned back to school, this was a good change of pace for me as I was able to get back to the work.

Specifically this week I continued to expand my knowledge of the gear train the engineering and the protocols. Specially altering, checking the wheels and servicing the barrel.

This although straightforward had certain complexities that made it a new experience being both challenging and rewarding.

Origin : Malaysia

Age : 28

Watchmaking class : 2 years Fullskill Program

Current Mood: It’s good to be back after the summer holiday.

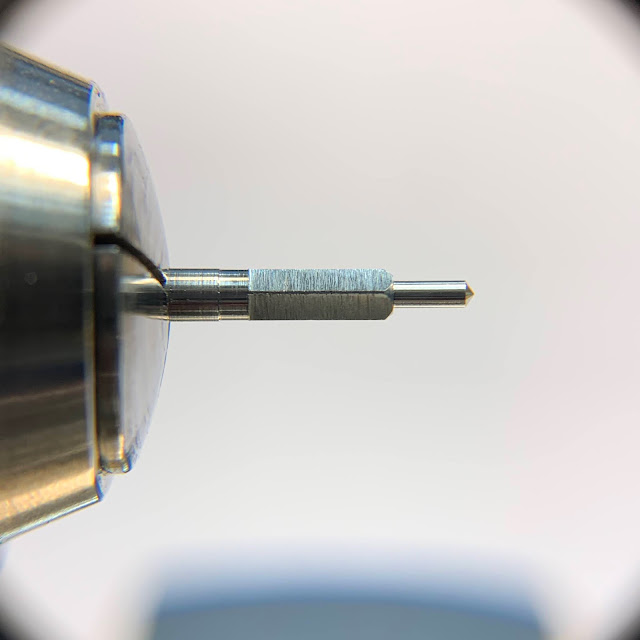

Managed to finish the winding stem restoration project. Firstly, calculate all

the required dimensions using calipers and profile projector. Made a brass

piece sample and a steel winding stem is then produced with better

finishing and better fitting. I am very glad with the results although the

polishing could be better. Looking forward to next week. More micro mechanics!

Alex

Origin : Kaohsiung, Taiwan

Age : 27

Watchmaking : 2Y Fullskill Program

Current mood: n.a.

STEP 1: REPAIRS! (PIERRE)

Pierre had an issue with one of his repairs, here he is analyzing if there was a problem coming from the escapement as the new Witschi timing machine has the possibility to compare both sides (entry and exit) noises, this gives us the possibility to compare the amplitudes, for entry and exit sides, for example, if one pallet had a deeper total lock it would have lower amplitude on that side of balance arc.

STEP 2: QUARTZ! (TECHNICIANS)

The technicians also learn to analyze quartz watches.

STEP 3: PRIVATE REPAIRS! (JAMES)

STEP 4: RESTORATION! (MICHAEL)MICHAEL WORKING ON HIS RESTORATION PROJECT.

WITH THE REAL ONE AND THE BRASS PROTOTYPE

PROTOTYPE LOWER, UPPER IS THE REAL ONE.

HENRIK's WORDS:

First week of school after summer holidays!

It feels great to be back at normal work again.This first week was also nice

as we learn a lot of new things, Markus got introduced to two new subjects for

the gear train course; inspecting wheels

for faults and truing them in the flat as well as how to service the barrel

with mainspring. The technicians also learn several new things; Automatic and

calendar mechanisms, how to water resistance check a watch as well as how to do

the final control of the completed watch repair, Michael completed his winding stem for

an antique pocket watch where he had to learn how to design a new one as it was

missing. During my break I also met with Peter from The Naked Watchmaker and we

did some more projects together which was really nice! enjoy one here; https://www.thenakedwatchmaker.com/blog/2020/8/5/school-watches-le-locle-1941-1945 I also got invited to

talk with Dan and Johnny at the In The Metal podcast That was a new experience

for me as it was also live, you can find the talk here; https://www.youtube.com/watch?v=HoTAWSZHeOM it was very fun for sure! See you next week and have a great weekend!

No comments:

Post a Comment