Last week we had watchmakers to join the restoration course, and they were here to learn some restoration skills and get some tips and tricks. They learn how to use the lathe to cut a wheel and also how to use a profile projector to make a missing part from the movement, gold plating, sirface finish restoration jig boring etc.

This week we had theory for the classic chronograph, ETA 7750 chronograph, and the modular chronograph for the base movement. Before we start adjusting the movement, we made some tools to help us to do the job easily. After that,We learned how to adjust the chronograph with the Column wheel to function, and we also learned how to dissemble 7750 and the module one. The classic chronograph with the column wheel is much more beautiful compared to the other two. Learning how to make the right tension for the spring is really important and it is not easy. The components adjustment for chronograph also not an easy job, each adjustment will affect another. However, all in all, it is fun to work with chronograph movement.

This week we had a visitor from Malaysia, Adrian. He works in a watch shop in Malaysia as a sales for few years, and now he want to learn more watchmaking skills for himself. He mention that it is really hard to find a school that he could learn the skills he wants. Finally, he found our school and came for the bench. We think he will be here soon to start his watchmaking learning life.

Hour wheel cutting

Hand filing the yoke

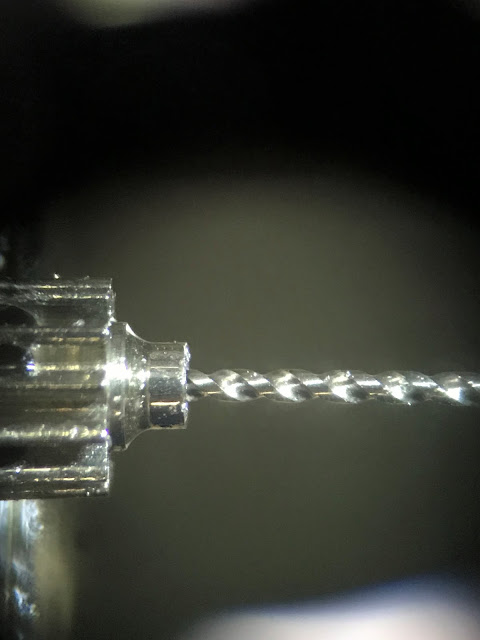

Shorten the normal screwdriver for the chronograph adjustment

Add a torque drum for the screw driver

Hand made key for Column wheel adjustment

Classic chronograph Valjoux 22

|

| Peak to peak (not good!) |

Nice tool to check the minute jumping moment

Replacing broken rubbed in jewel

Looking good with some cleaning up of the surface too.

Adrian visited for the taster course/bench test