There are so many amazing watches, clocks, and watchmaking tools. The most amazing things are the bird guns and the caliber 89 pocket watch. It's impossible for mechnical watch enthusiasts to see all the things in one day. If you are also a watch lover, you must visit this museum.

This week, we are practicing burnishing for the ultimate micro mechanic exam. Burnishing is much harder than we expected. We still need lots practice to meet the goal, perfect black polish. In addition, this week is the last week for Shuai, class 2017. He is soon going back to China for his own workshop. Hence, this week we went hiking and bbq to celebrate his graduation. Wish he all the best for his future watchmaking career.

|

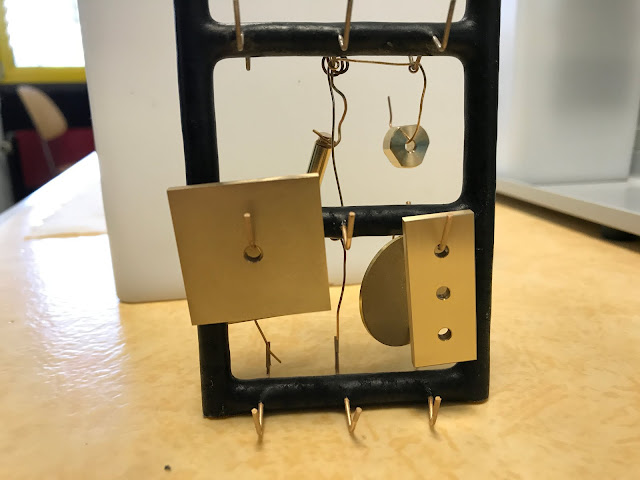

| Shuai's last project in school. Re-pivoting for a clock part. |

|

| This stick is way too long. > < |