WEEK 175

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

This week we returned back to the program, it took a few days for the skills to get back to normal. However, we are covering the last section of the course on quartz watch and Chronograph. We are enjoying to work for our own repair movements. They need to be done to reach a certain amount to be allowed to take the Final exam. Finally, the course is going to be done and we are looking forward to celebrate soon.

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

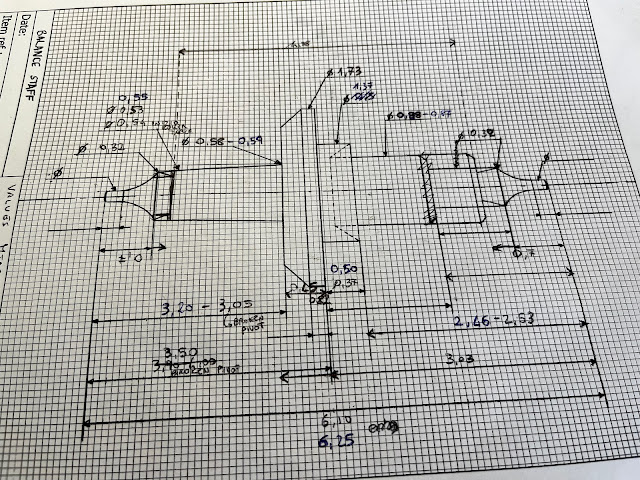

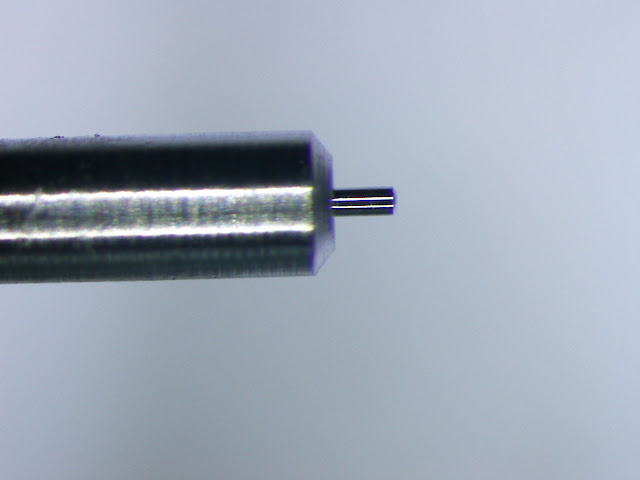

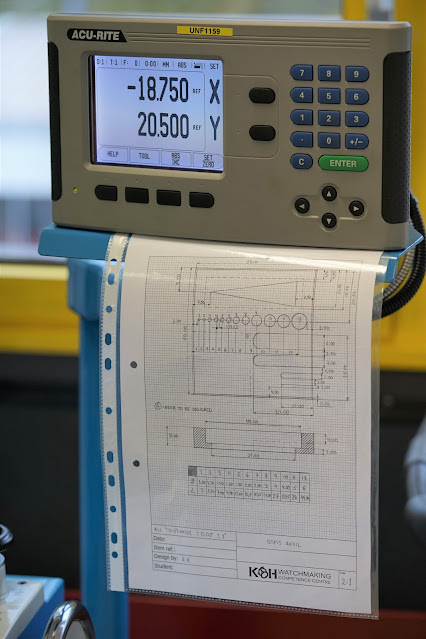

This week, (8-12 August) Henrik introduced Tetsu and Dean to the making of winding stem slots. This included guidance with the shaping of slot gravers from tungsten carbide. After a tutorial on the Agathon grinding machine, Tetsu and Dean made their slot gravers, then got to work on shaping and cutting slots in practice brass pieces prior to preparing some blue steel pieces from which to cut slots for further practice. This will continue into the following week in preparation for them to make fully functional winding stems.

Have a great weekend everyone!

Tetsu and Dean

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

After doing all the barrels, David and I had the jewel intro, being the last topic before the next exam. Fitting, removal and adjustment within the mainplate and bridges. Kinda fun to get a feel for endshake differences of a few hundreds and wheel positioning for divisions. Will be interesting to apply this to the smaller movements. Next week we can do some practice exams that encompass all the movement topics covered so far (winding/setting, wheel truing, barrel maintenance, jewel adjustment). Nice!

STEP 1: QUARTZ WATCHES! (TECHNICIAN)

Technicians learning as much as possible about the quartz watch!

STEP 2: JEWELED BEARINGS! (RENATO & DAVID)

Not all jewels in antique and vintage watches look the same!

Renato and David started to work with the bearings of the watch, mainly jeweled bearings, these are some of the typical anvils/stumps and pushers used to deal with various situations regarding them.

STEP 3: OVERHAUL OF HEAD STOCK! (KHWCC)

One of our Schaublin 102 lathes needed a new fresh belt as the other one was disintegrating from 12 years of use :) also it got fresh new ball bearings and a complete check up, a Spa treatment for a lathe!!

STEP 4: FRIENDS! (EVERYONE)

Nice to be back among our friends!

STEP 5: BOOKS! KHWCC)

We also got a donation of these two books for the school library which will come in very handy! Thank you!

STEP 6: RESTORATION! (FRANCESCO)

Francesco got this project from Renato to later make a balance staff for!

STEP 7: WATCHES! (ÅSMUND)

Asmund got this project for later repair!

STEP 8: WATCHES! (DAVID FULLSKILL)

David got this nice school watch to later overhaul!

STEP 9: HARD WORKING! (TECHNICIANS)

Technicians back on their benches working hard on the last watches before the final exam!

HENRIK's WORDS:

Finally back to normality! The summer vacation was really good though, I only had one option, to stay in Switzerland due to passport issues, but it turned out great as the weather was just the best! not too hot and not too cold, just the perfect summer! The technicians got introduced to the quartz watch and continued on their repairs as well. Renato and David started to work on endshakes, divisions and clearances of the gear train by learning to replace and adjust the jewels! Tetsu and Dean started practicing slots for winding stems, Asmund and Francesco working on making various size pivots and Robert preparing some tools before starting to make pivot gauges! It was a very nice and also productive first week back! have a great weekend everyone!

.jpeg)

.jpeg)