WEEK 155

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

This week we have learned all about the Escapement and how to adjust the Pallet jewels with the escape-meter.

My seven movements pallet fork division and Escape end-shake still have not been finished yet, but the exam is coming soon. I have to push myself more and also maintain the quality of my work.

All of the Technicians are working very hard included our T.A., he ’s always be there when we need him.

David have made his own steel pusher for removing his pallet for staff.

Kate is focusing on her pallet jewels adjustment with escape meter.

Lani is working on her seven movement divisions and endshakes as well. She has been very focused on restoring a cal. 2892 pallet fork that had many issues due to bends in it.

A Verachai

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (21~25 March) Dean & Tetsu swapped their work places.

Dean tried the ACIERA F1 milling machine, while Tetsu went back to his bench and did some filing and sawing.

Our current jobs are particularly labour–intensive as we have spent more than 3 weeks on the same tasks, but both of us are working on greater than 2 items concurrently.

So far, we made only a few mistakes and are slowly advancing with the projects.

We keep pushing ourselves, but not rushing to see the light at the end of the tunnel, so stay tuned!

We wish you all a great weekend!

Dean & Tetsu

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Started another restoration, because balance staff is the next topic. It's a split second pocket watch movement with a pretty much destroyed balance, but also some other issues. First task this week was taking all the measurements for the balance staff. After that I started working on the roller table restoration, more precisely, making a replacement for the broken roller jewel. Grinding a donor jewel to size took quite a while, but it's a great exercise for future restorations. I'm almost done, so I think we can fix it to the original roller table Monday. Looking forward to starting the staff afterwards!

-Renato

STEP 1: TOOLS! (FRANCESCO)

STEP 2: LONGINES! (EVERYONE)

STEP 3: THE SWISS LEVER ESCAPEMENT! (TECHNICIANS)

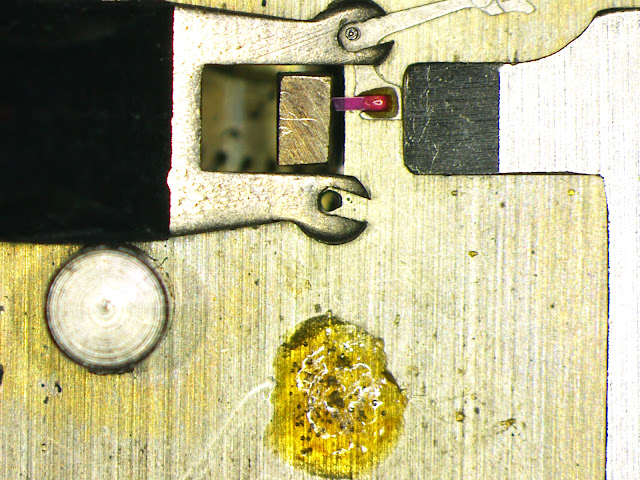

Technicians checking the division between escape wheel and pallets!

Pallet adjustments!

Checking guard pin division!

STEP 4: JEWELS! (RENATO)

Checking the fit!

the interacting fork it has to be able to work with!

Renato modifying the fit of a roller jewel to fit his antique roller table!

STEP 5: BOOKS! (ROBERT)

Robert came with this very interesting book!

If doing research about alarm watches this seems like a very good reference!

STEP 6: GOT IT! (DAVID (TECHNICIAN))

David needed a mainspring for one of his pocket watches and received the original brand one! Hopefully the steel is still good and not set!

STEP 7: MICROMETERS! (FULLSKILL)

Some of the Fullskill students got this very handy micrometer! Excellent for measuring balance staffs!

HENRIK's WORDS:

The visit to the Longines museum was really amazing and we had a great very knowledgeable guide who kept us entertained during this very interesting visit, I believe some of us became serious fans of this historical very important Swiss watchmaking brand! This week we also got two new taster course students all the way from Australia and the Philippines which was really nice! The technicians started something new with the Swiss lever escapement; how to adjust the pallets (for function, safety and performance) this is where it gets really interesting as there are specific rules that must be respected to the adjustments that reminds very much of a game! Very fun times indeed!! Renato did something very interesting on one of his pocket watches; modifying an antique jewel to fit one of his pocket watch balance rollers which was broken, very interesting! Francesco also finished plating his tripod tool and practice taking some cool photos of it :) Very intense but fun week! Have a great weekend everyone!

.jpeg)