Last weekend, our alumni, Tryggvi and Robert, came back to school to visit and share their experience for working in the industry. Both of them have a great job now. They shared lots of reality that how most people work in the real watchmaking industry. Although we may not use some of the skills we learned from school, it's still good to learn as many skills as we could. We will never know when we will have a chance to use them. Tryggvi shared what he learned from his work, such as how he used shorter time to oil parts. In addition, he also shared his bench test experience when we find a job. He said the most important thing is to keep everythig clean, and don't hesitate to ask questions if we don't know something. It's really good to hear someting from the people who work in the watchmaking industry.

On Sunday, Henrik took us to France for a flea market. The flea market is for watchmaking tools and parts. We all got some good quality second hand tools in that market. we are really glad we came there.

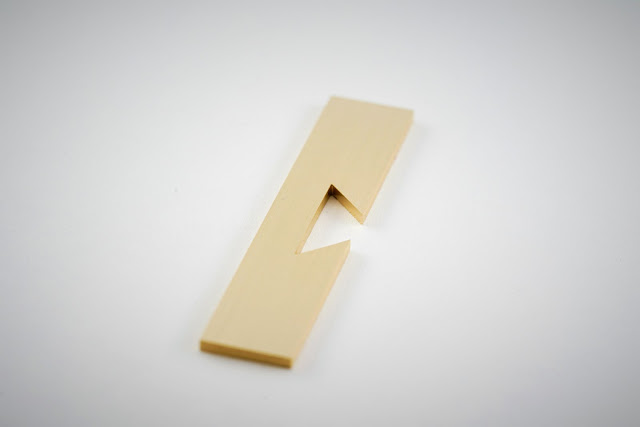

This week, we all have different journey. Stan finished his first balance staff, and it took him about one week from learning to finish making. He also try to finish some tools before December. Sif and Yi-ting started to learn how to make a balance staff in a morden way. Although it's quicker compared to the traditional method, it still took many days to learn to make one. Cj is learning how to cut an hour wheel, and this is also one of our exams. This exam isn't really difficult compared to winding-stem or pivot gauge. However there are lots of details we need to remember if we want to get a good result.

Now, our school provides short-term course for the people who work in the industry. Last course, three professinal watchmakers came to learn the micro-mechanics and restoration for balance staff.

Our school also provide other courses for different watchmaking techniques. If people want to learn something new, it's a great chance to learn here.

Our alumni, Tryggvi and Robert came to visit

Tryggvi shared some experience

Flea market for watchmaking tools in France

Sif measured the total lengh of the balance staff

Yi-ting measured the total lengh of the balance staff

Stan's first balance staff

CJ is cutting wheel on the lathe

Professional watchmaker took notes for the balance staff

Professional watchmakers turning balance staff's