Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

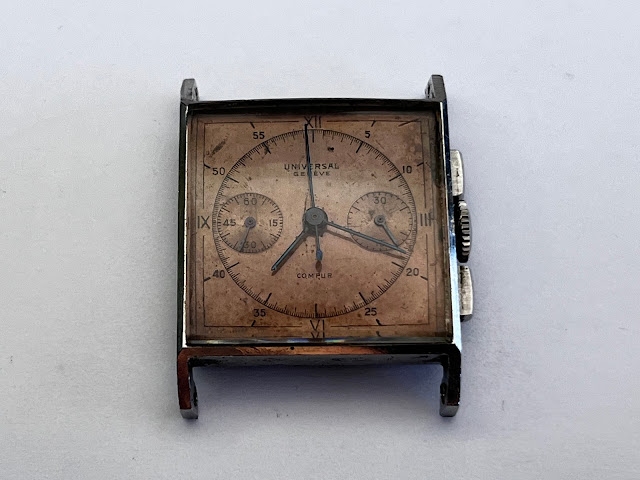

This week was pretty cool since I could finally start the work on several vintage chronographs who need a service or repair. Also interesting because they all happen to have different (mostly) inhouse movements, so I see all the different layouts and construction. Quite a nice feeling to disassemble everything and have each single part going through my hands and later assemble again knowing each movement is in top shape. They all need a service and adjustment, so it will be nice to have them properly running at some point. Next thing is to go through winding/setting, mainspring, end shakes etc. we learned already about. Looking forward to it!

-Renato

STEP 1: HAIRSPRINGS! (AWCI INTERNATIONAL GROUP)

It was truly inspiring and wonderful to teach this class!!!

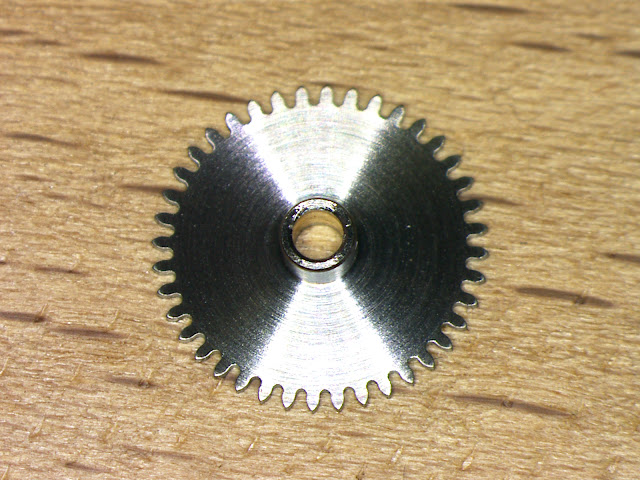

STEP 2: GEAR MAKING! (FRANCESCO)

Francesco practicing making the hour wheel!

STEP 3: WATCHES! (RENATO)

Renato subjected a wristwatch chronograph collection for repairing!

STEP 4: BOOKS! (KHWCC LIBRARY)

Thank you for making the school library more interesting!!

STEP 5: HAPPY BIRTHDAY! (ROBERT)

Happy Birthday sweet tooth Robert!!

STEP 6: POP-UP SECOND HAND WATCH TOOL STORE! (KHWCC)

Sabri came to the school with his collection of second hand watchmaker tools which was very nice for everyone especially the hairspring course students!!

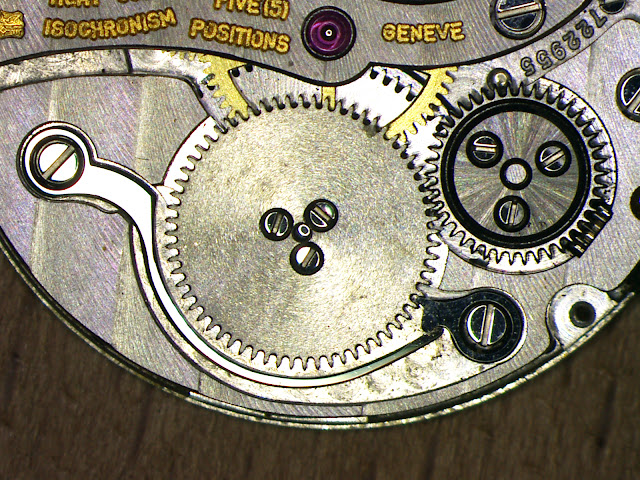

STEP 7: MOVEMENTS! (DEAN)

Dean Submitted some very interesting ultra thin movements that he will later in the course repair!

HENRIK's WORDS:

This week we had a group of 5 watchmakers all members of the AWCI https://www.awci.com/ to learn about hairsprings, they were all very passionate and enthusiastic! we covered a lot in a very short time! they learn to rivet the staff to the balance, install the double roller, perform static poising and truing the balance in the flat, they then continued to pin a raw hairspring to the collet, vibrating/counting it to the correct frequency, align the inner pinning point to the regulating point, make the double bend, regulating curve, and studding it up to the bridge and then they also practiced making it flat and centred under the bridge before doing the timing, very intensive week and they all went home with their own balance completes! The Fullskill students continued progressing mostly with the same work as last week! It was truly a fantastic week!! Have a great weekend everyone!