WEEK 157-158

Team A

Origin: Thailand & USA,

Name: A, Kate, David & Leilani

Watchmaking class: Technician

Current mood:

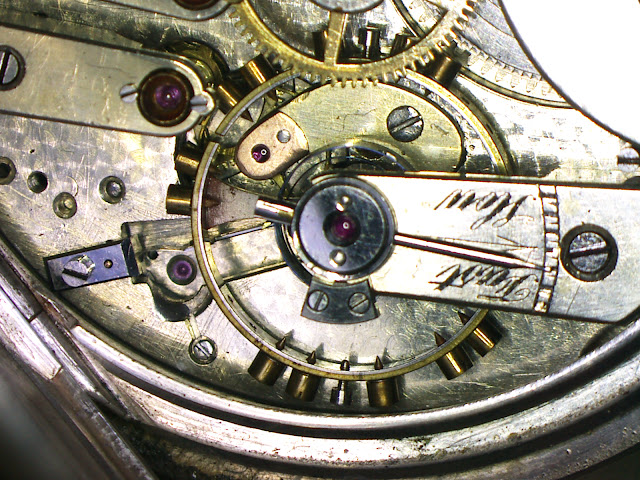

It’s Spring but it has been raining a long this week, we are still practicing on the seventh movements. The escapement exam is coming next week and we've got already 3 trial exams. The trial exam is quit benefit everyone in the case of practicing, preparing and we are be able to improve the performances very well. All technician students were studying diligently to guarantee that everything was as flawless as possible in the real exam.

Kate Raksina

Team B

Origin: Japan/Switzerland & Canada

Name: Tetsu & Dean

Watchmaking class: Fullskill

Current mood:

This week, (11~13. April) + last week, (04~08. April) Dean & Tetsu gained new experience, which helped them advance.

Dean comfortably finished his work on the HAUSER 2A3 Jig Borer for his Polishing Tripod Base Plate and moved on to the Schaublin 102 Lathe with a milling attachment for the bolts & nuts.

After completing all the nicely decorated pieces, which were very simple but amazingly stunning & practical, he immediately went to the plating process, making them look even more beautiful!!

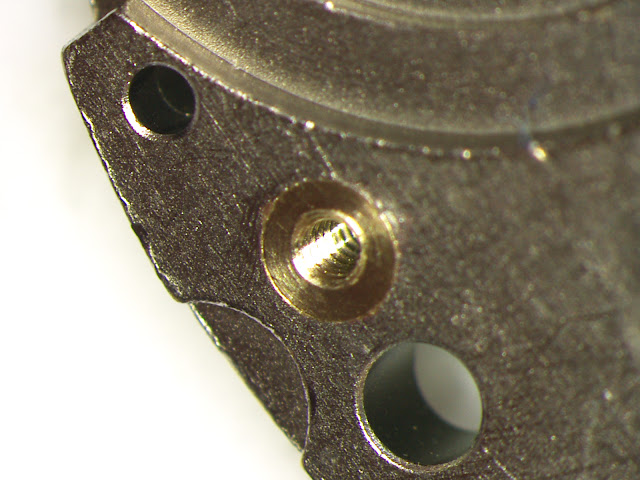

Tetsu tried the HAUSER Jig Borer for the first time for his Brass Anvil, making 12 holes in different sizes with drills and an adjustable boring cutter.

He made 2 pieces in a row to get familiar with the machine.

The key factor is again the set-up. Once it is done properly, there is nothing to worry about.

He is now sawing & filing to make a triangle-shaped hole, then going on to the surface finish.

We have learned how to handle most machines here for tool making and will continue working by using the methods and the techniques for the other tools.

We had a special visitor on Friday, 08 April; Mr Robert Michelsen, who used to be Henrik’s student and business partner for sometime.

The details may be mentioned somewhere else but we had a great time with him and gain lots of valuable information. Thank you, Robert!

-Dean & Tetsu

Team C

Origin: Switzerland, Norway & USA

Name: Renato, David, Francesco, Åsmund & Robert

Watchmaking class: Fullskill

Current mood:

Spent the week doing jewel shaping/polishing. Very important task in restoration, so I am glad that I could get a good feel for the hard material and how to work with it. Also learned how to open and close beveled jewel seats, i.e. mainly how to rub in the new jewel I made as part of previous task. Looks pretty good for the first time I did it, I think!

-Renato

The last 2 weeks have been all about making winding stems using the small 8 millimeter lathe and hand-held gravers, and then putting them through the heat treatment process. Not a whole lot to report: repetition, repetition, repetition. Getting comfortable making the stems to the tight tolerances on the drawing, thinking of ways to speed the process along, leave some tolerances big so work can proceed "with vigor" on neighboring sections, etc. A whole new learning process, the winding stems are being made a little faster with each one produced.

-Robert

STEP 1: EASTER! (EVERYONE)

Thank you Svenja for the tasty treat!!

STEP 2: JEWELS! (RENATO)

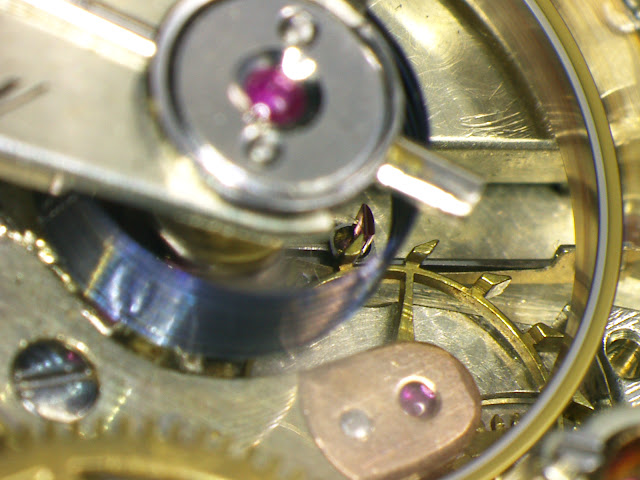

Renato finished his jewel modification! the right hand jewel is the broken old one. Jewel sett up and checked for concentricity with the centring microscope in the Schaublin 70 lathe!

Jewel ready to be modified!

He reduced the diameter to fit the setting and ground two bevels on both sides so that the setting can be rubbed over to keep it in position!

His modified jewel installed in the movement!

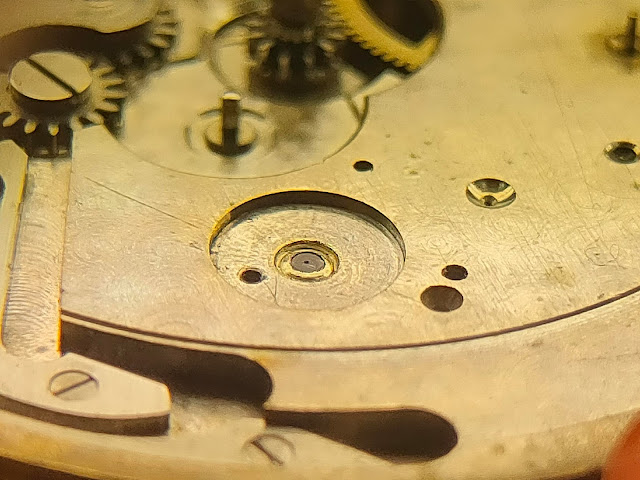

STEP 3: BALANCE STAFF! (RENATO)

Before making the staff he had to find out what size it needs to be for the specific movement he will be making it for!

Renato getting ready to turn the balance staff in the 70, he will do it in two stages; first he will turn the body of the balance staff with the cross slide as its very fast, precise and minimal risk of making a mistake! And since he will do it with the help of the microscope he can comfortably measure and see everything very precisely without having to take out the staff from the collet which would make it eccentric if taking it in and out of the collet. In the second stage he only has to turn the cone for the roller and the two end pivots which he will do by turning it between fixed centres by hand in the small Horia lathe to keep it perfectly concentric, and at the end he will burnish the pivots.

First stage done, only cone and pivots left to do!

STEP 4: THE SWISS LEVER ESCAPEMENT! (TECHNICIANS)

The technicians were very busy with adjusting the swiss lever escapement!

STEP 5: MACHINING! (DEAN & TETSU)

Both Dean and Tetsu were very busy machining their tools, Dean making his screws here with the Schaublin 102 with the milling attachment!

STEP 6: GIFT! (DEAN)

A nice gift! Thank you Dean and his girl friend who came to visit him!

STEP 7: TOOL MODIFICATIONS! (DAVID)

David (Fullskill) felt that the burnisher he was using was a bit on the heavy side so he made a lot of holes in the handle to lighten it to hopefully receive some more sense of feel when burnishing!

STEP 8: VISITOR! (ROBERT MICHELSEN, ICELAND)

We all benefited greatly from having a relaxed Q&A with Robert about his watchmaking experiences!

STEP 9: BOOKS! (KHWCC LIBRARY)

Svenja found this very interesting book and added it to the library. Thank you Svenja!

HENRIK's WORDS:

Soon Easter! Last week was very busy as everyone is trying to finish as much work as possible before Easter holidays so we had no time to organize a blogpost last week. Last week we also had David all the way from Taiwan taking the bench test/taster course which was nice. As I write, the technicians are in the escapement exam which is very good timing for them as they have then completed more or less the escapement course! Renato completed his jewel modifications and rubbed it in to the mainplate, he then started to design and make the balance staff for the same watch! David modified his burnishing tool handle to make it lighter to get more sense of feel when burnishing! Francesco also had his winding stem exam, good timing for him as well as he will come back to his school watch after the break! Asmund and Robert continued making winding stems, and Tetsu and Dean continued on their tool manufacturing. We had also a very nice Q&A with Robert from Iceland who was my first teacher many years ago before Michael and now works in his family business in Iceland, it was really great to see Rob again!! Very interesting, creative and intense two weeks!! Have a great Easter holiday everyone!

.jpeg)

.jpeg)