Starting this week strong. Our professor, Michael along with his student, Bernd returned from Andermatt. Michael lead a week-long interactive horology program in The Chedi, for members of the Bentley Mulliner drive experience. Michael’s program involved a variety of basic watchmaking skills as well as some history of horology and motor sports. A presentation was given on the relationship between Bentley and Breitling, discussing the uses of chronographs in the world of cars.

|

| Michael leading the class, next to Bernd |

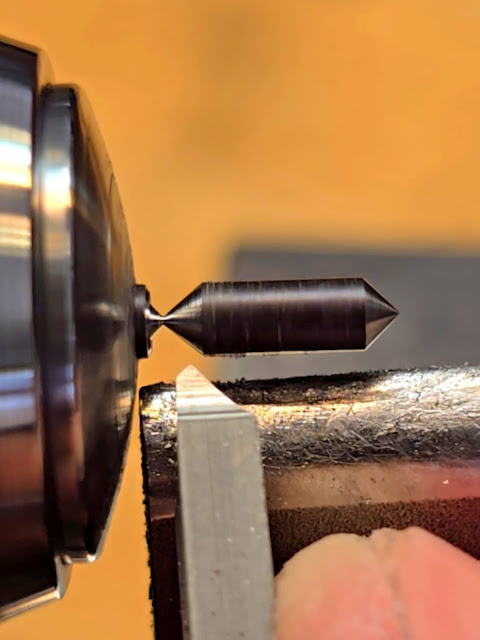

Bernd, serving as Michael’s assistant, demonstrated the process of hand turning with a watchmakers lathe to make winding stems. Showing the amount of work need to make a simple part by hand.

|

| Bernd demonstrating some hand turning |

|

| Michael testing the student’s watches in the timegrapher |

Back to Le Locle, the students are keeping busy. Craig is making progress on his school watch. Using the lathe to make the base plate for his calibre. It is shaping up to quite a beauty.

|

| Voila |

Cesar (myself) is prototyping some dial possibilities with brass. A task much harder than expected, for every process a jig needs to be made, and for every jig another jig has to be made. But we’re making progress.

|

| Prototyping |

As for the new students, they are now learning to operate one of the many machines in our school, the drilling machine. Chris has also been having some fun with the school new 3D printer and made himself a screwdriver holder.

Myself again, update from last week. This week I finished the restoration of a Bergeon pallet fork tool. Not a quick job.

|

| Kept the steel blue |

That’s it for this week. Thank you for reading and until next time.

|

| Artemy bids your a good weekend |

.jpeg)