|

| The magnetic graver man bids your hello |

Another week comes to a close. The new students have spent the last few days familiarising themselves with some of the larger tools and their attachments. Here they are being taught how to make threads and taps, a crucial skill in watchmaking.

|

| Making a screw |

Cesar is working on some dial prototypes, so here he made a jig to speed up the production process and save time centering. This jig is set up so that the dial can easily centered on the center hole and the sundial hole, with slots for the dial feet. This way the jig sits straight into a collet.

|

| Dial jig |

|

| The back of the jig |

Cesar has also finished polishing the pallet fork jewels of an old pocket watch. A lot of effort but look at them shine.

|

| Before |

|

| After |

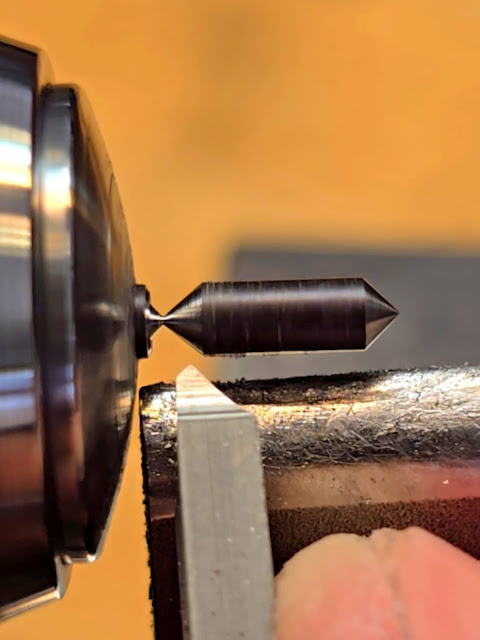

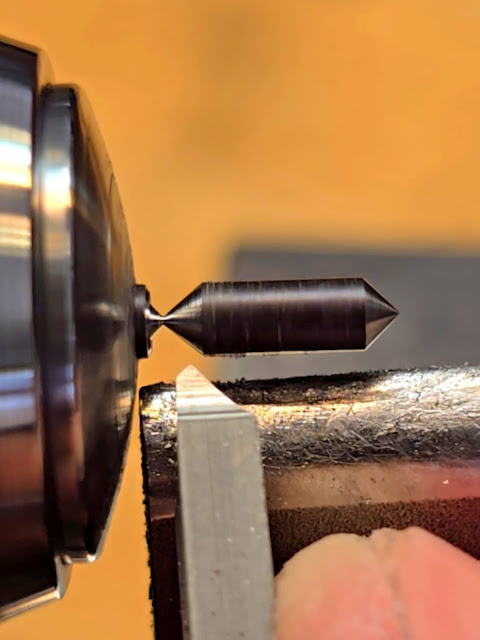

Bernd and Louis have started the long road which is pivot gauges. A delicate and repetitive task which will take a few months to master. First comes the preparations, making blanks and jigs.

|

| Making a blank such that both cones are centered |

|

| Jig to hold the blanks on the watchmaker lathe |

|

| In action |

That’s it for this week, until next time.

wow

ReplyDelete